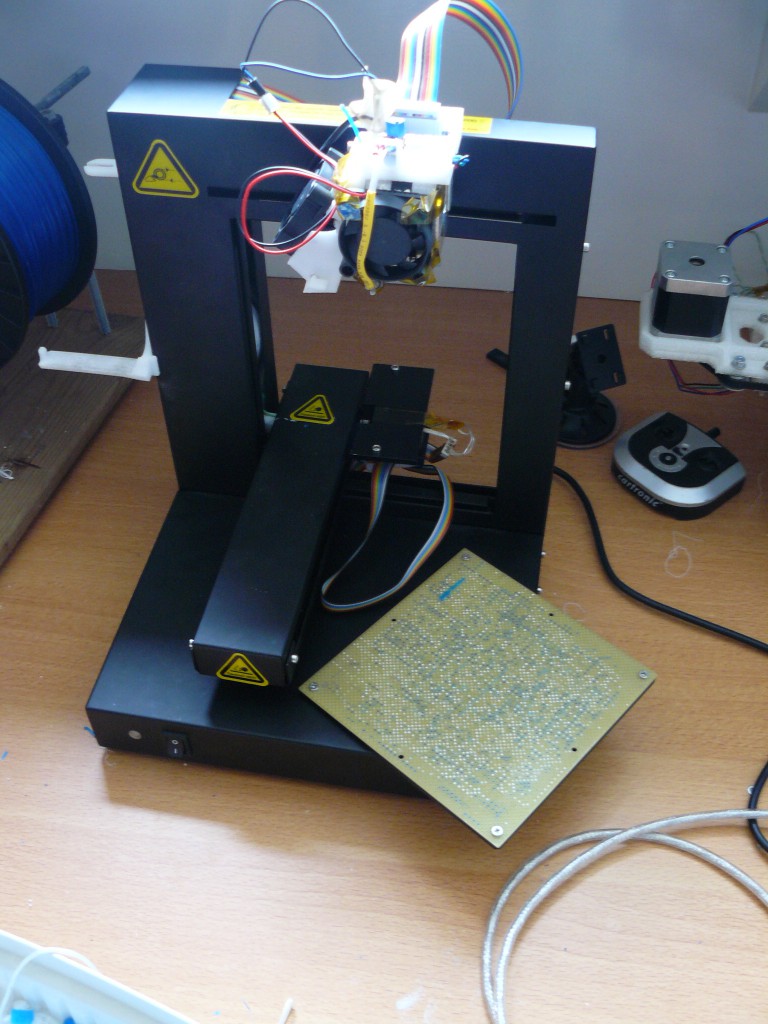

Plan B is live, response has been mostly positive. Tuesday 19 August I posted Plan B on the internet. It had been a year in the making at that point, but I finally was happy enough with it to post it. It still needs many improvements, but I can make those in good time, and maybe there will be more people from this point onward. I will tag some Blog posts with Plan B from here on out, for the people that want to stay updated on Plan B, but don’t care about the rest.

Just how strong are these prints anyway,

I had people asking me how strong these prints are. I have destroyed 2 prints, just to satisfy anyone curious. (I hope you are happy now)

I first loaded up the torus with 14kg. This was held without any sight of damage. Then I found someone (around 70kg) willing to stand on the part. The part broke, but only after the person applied the full weight. Then I found a misprinted vase. The person also stood on that. The same thing happened. It didn’t hold, but only after full weight was on the part.

I am quite surprised at the strength of the part, though I am a bit sad that the torus broke (I will print a new one soon). These parts are made of gypsum, glued with CA. Neither have remarkable mechanical properties.

In short. The parts are quite strong. Maybe with the current materials not FDM printed ABS strong, but drop onto concrete from few meters without damage strong. More exact data will follow as I will do some more exact testing on strength in the coming few months.

I tried to improve the speed once, it was awful,

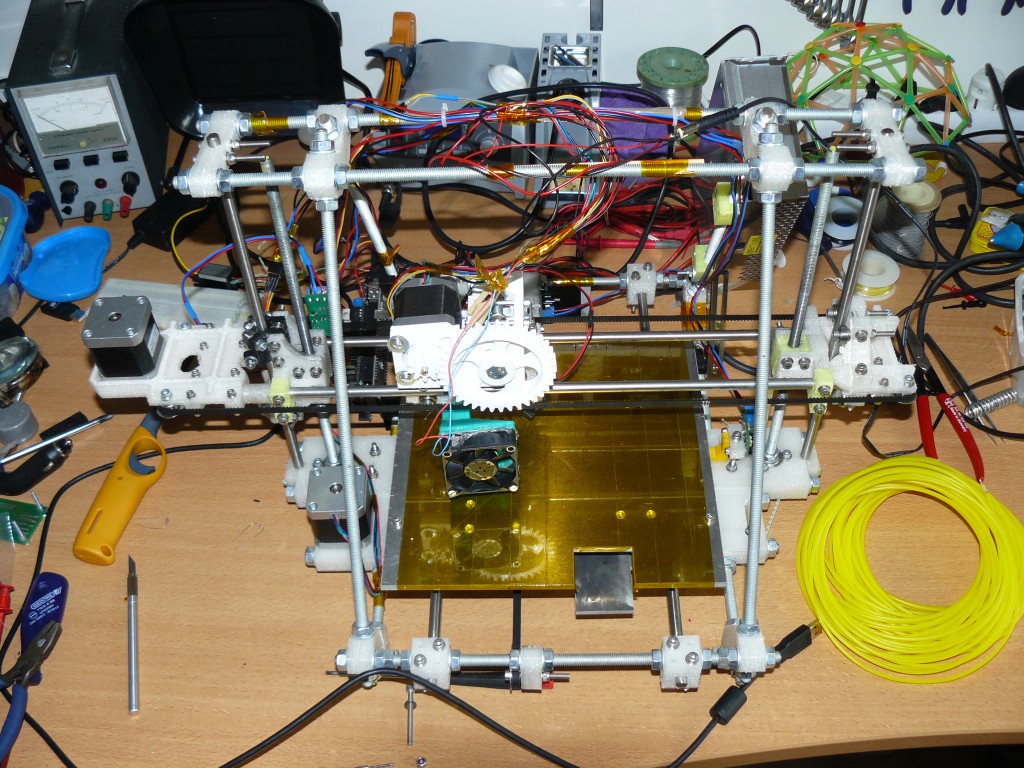

I tried to speed up the printer to 120mm/s. While mechanically this is a piece of cake (the printer had no trouble moving at 120mm/s) the electronics didn’t like it quite as much. The result was missing steps and thick lines at some points. The problem is that the Atmega 2560 with the current firmware simply can’t keep up. It can’t change the on/off state of the nozzles fast enough. In the future, there will either have to be: Better firmware, a better microcontroller or more of them running different functions in the printer.

Finally the Arduino haters out there have some reason to hate it (like they didn’t have it before).

I personally love Arduino, despite it’s flaws. The pure simplicity of the system has made Plan B possible, only now it is probably time to get something a bit more powerful.

When will stuff be for sale

People asked if and when stuff will be for sale. For people in Europe this can be quite soon, USA and the rest of the world maybe not (I don’t know shipping cost yet). Upon request I can have a few sets manufactured in maybe a week. Getting other materials is also a mater of ordering parts or printing them. The only thing is the boost demultiplexer circuit. I have a shipment of circuit boards currently in transit. When I receive these and they work, I can make complete functional kits. I can’t give exact cost of one kit, but it will be in the neighbourhood of €1000,-.

Please bear in mind that Plan B is an experimental printer. You are buying a prototype, a first generation. It will not work instantly, it will not work constantly, you will have to tweak a lot of things and do a lot of experimenting with materials. With that you can help making it better for future generations of printers. If after that demotivating speech there is still anyone who wants one, contact me. If I receive enough serious requests I will order a shipment of parts and either open a shop or get a local 3D printer part supplier to sell them.

Planned things:

With Plan B finally live, I am finally able to relax a bit. The past few weeks I worked really hard getting everything done. I will now calmly move on with some experiments I didn’t want to do without Plan B being posted.

Upgrading the spreader to a smaller diameter and make it rotating. I think some issues with the layers breaking up are caused by the spreader having too great a diameter. This pushed too hard on the previous layers. I am going to design a smaller and rotating spreader that can be made without a lathe. If this helps I will post all files and things required.

Ceramics printing. In the materials, I talk about printing in ceramics powder that can be fired in a kiln. I hope to do this as soon as possible. I will order ceramics powder, Maltodextrin and a bottle of sake and I will find a place nearby that has a kiln to fire the parts. I will show the results as soon as it is here.

I have looked around looking for a printhead with more colours and more resolution. Plan B will not be able to hold these parts, but perhaps a future 3DP printer will be able to hold this. The printhead in question is: “hp cn642a” It has an unknown amount of nozzles, at least 300DPI and 4-5 printheads. I also know several suppliers who sell empty CISS (Continuous Ink Supply System) cartridges for this printhead, making the conversion step a thing of the past. At this point I have no idea how the nozzle control even works, but given the fact that there are 38 contacts on the back, I doubt that there is any microchips in there, making control fairly straight forward.

With this I can make a printer that can print in full colour. The firmware can’t handle it yet, the software can’t handle it yet, the hardware can’t handle it yet, but I will try and make it happen regardless.

Input from you people

I am open to input from anyone reading this. What do you want to see printed? What do you want to know about the material? What do you want to see improved? What do you want to see tested? I can’t promise I will do everything, but I will try as hard as I can to help.