Table of content:

- Part 1: The beginning

- Part 2: Electric overhaul

- Part 3: PC power

- Part 4: Trying to print

- Part 5: INK!

- Part 6: Leaky pistons

- Part 7: Making printheads

- Part 8: (you are already here)

Everything needed to make the Z400 work is working. In March I got the Z400 from Wonko in Germany. Since then I have tested all the power supplies, secured the disc image in case the disc ever fails and added a transformer to run this 115V machine in the Netherlands. I have gotten the inkjet printer part to work, repaired the pistons and made new printheads that printed binder.

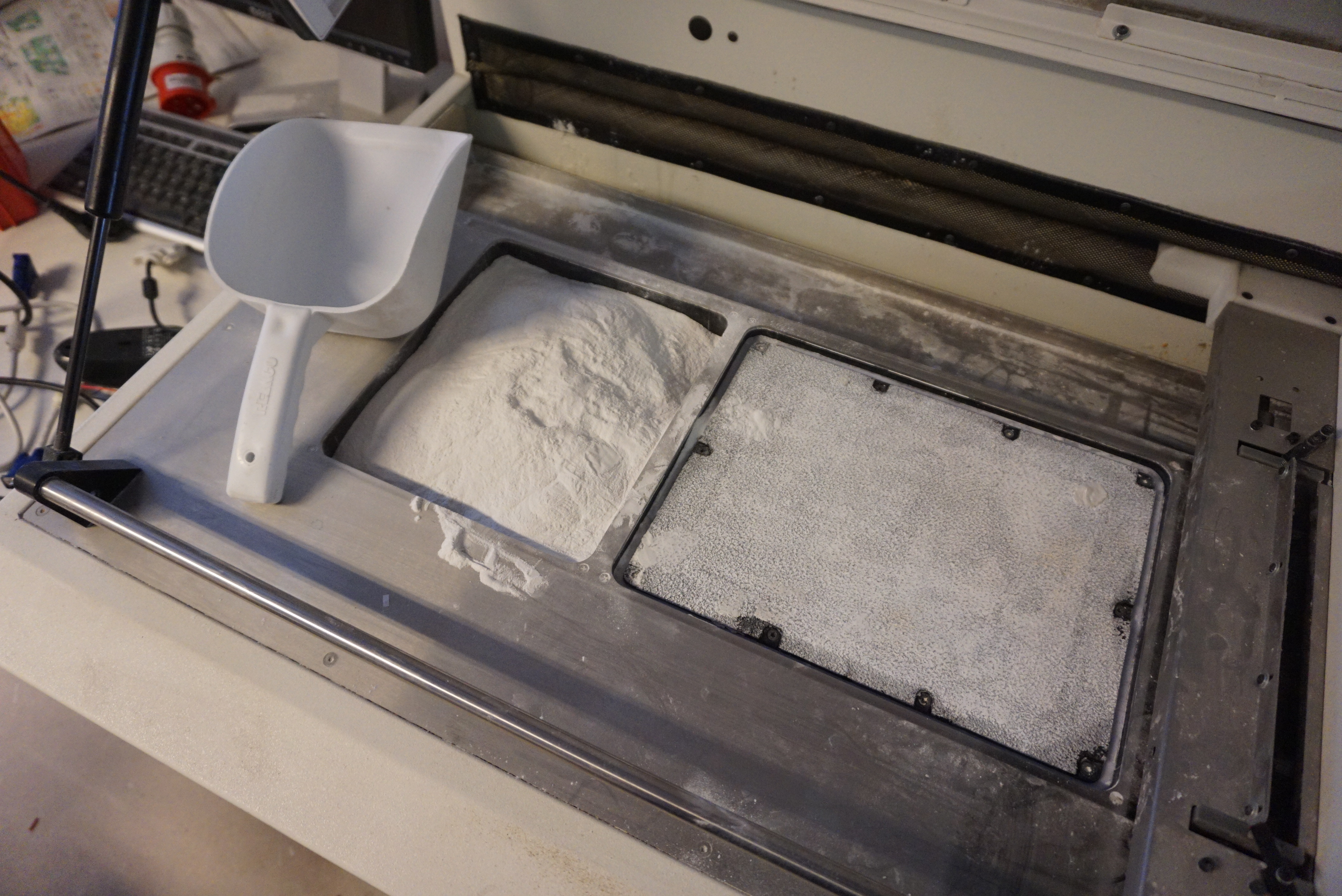

I filled the printer with powder I still had, then I hit ‘3D print’

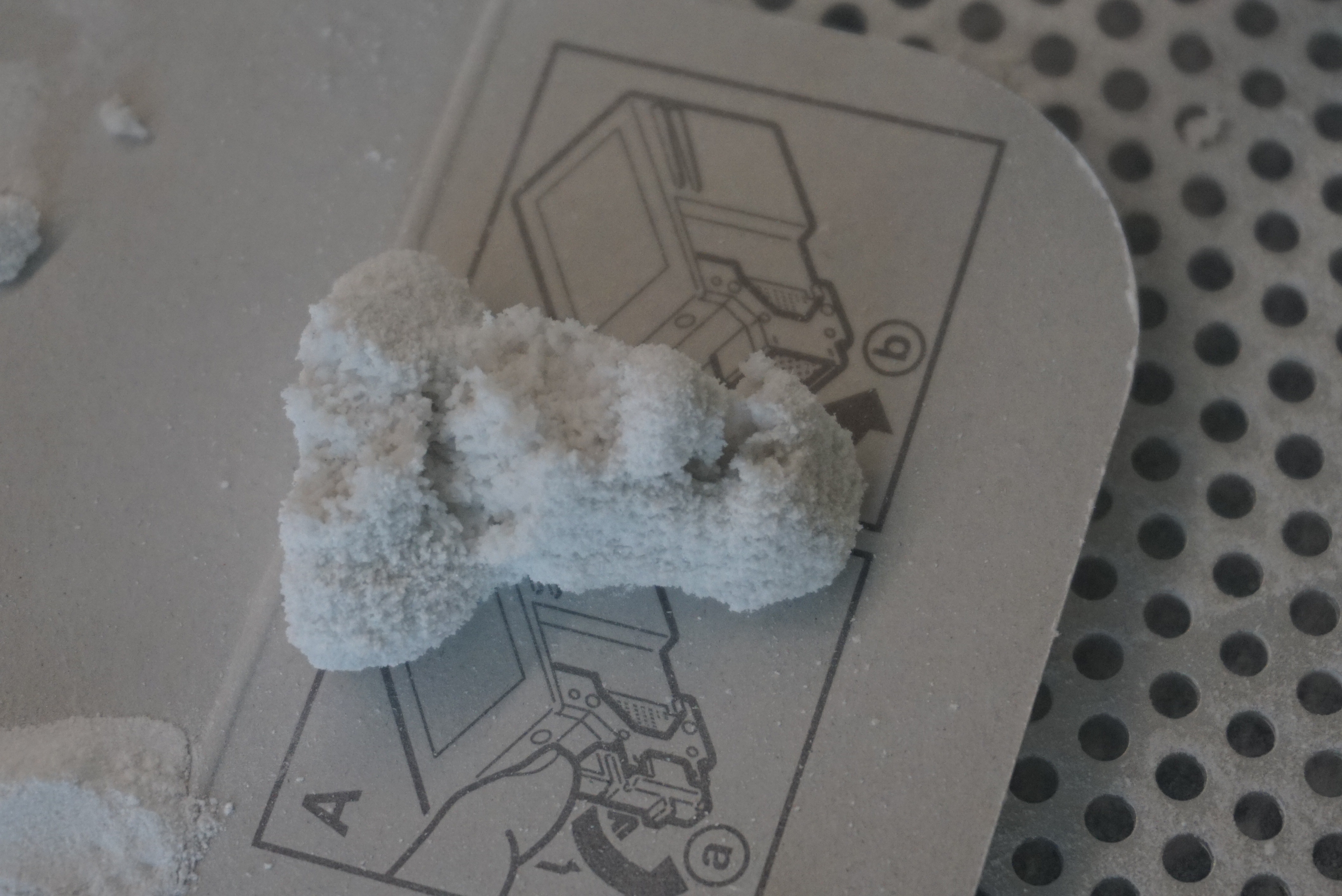

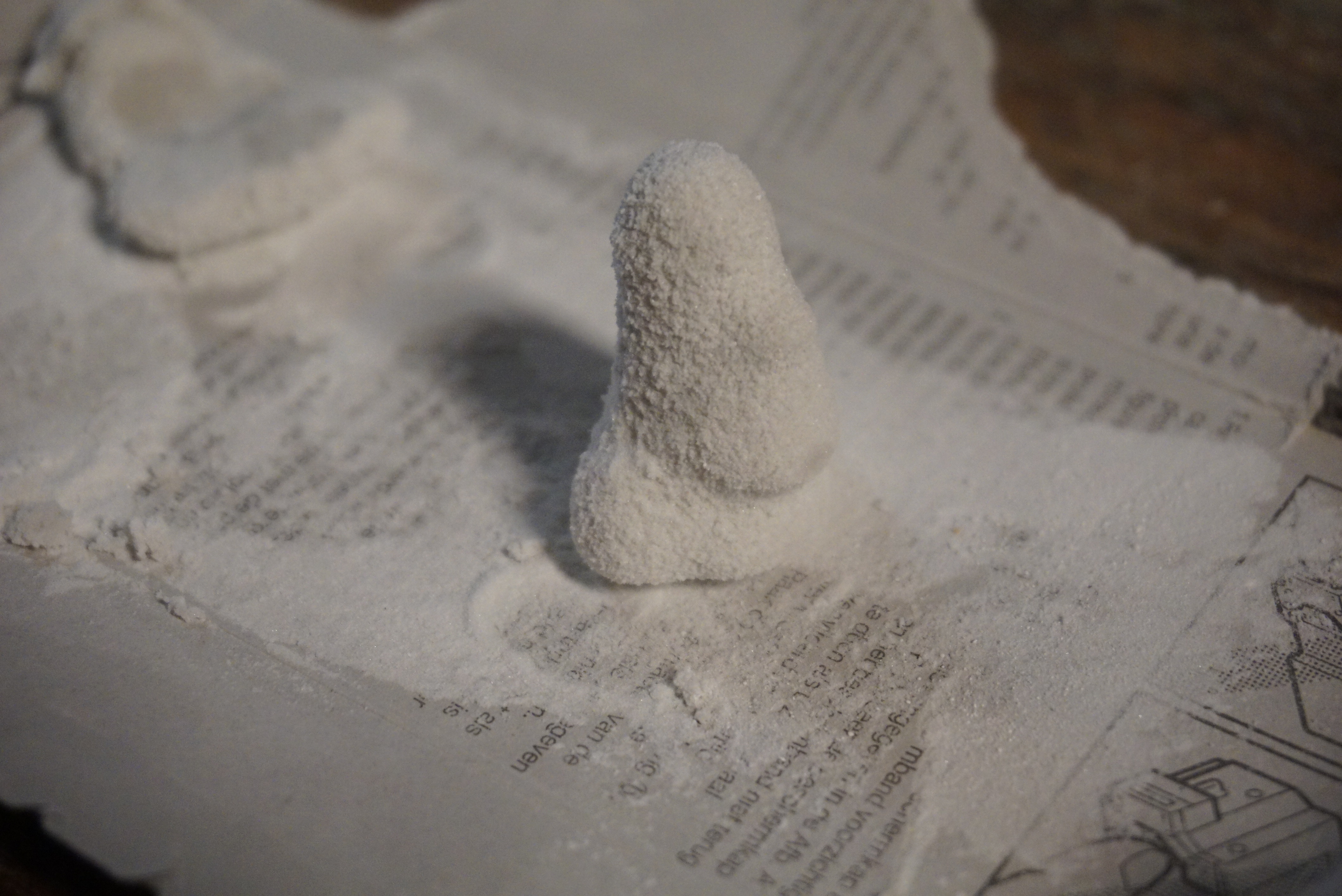

The printer worked great. Layer by layer I saw a part get made. So far it looked really good. Getting the part out after 30 minutes proved problematic, the part would disintegrate during cleaning. Another print was made, and left for a day to set. Lots of binder leaked into the surrounding unbound powder. I then printed at a lower binder percentage (75%), but was met with the same results.

So the conclusion: Yes printer, no powder. The powder I currently have requires special binders, not water with alcohol I currently have in there. I might still test that powder with the tiny amount of binder I do have, but I will run out quickly. It will be better if I get another powder.

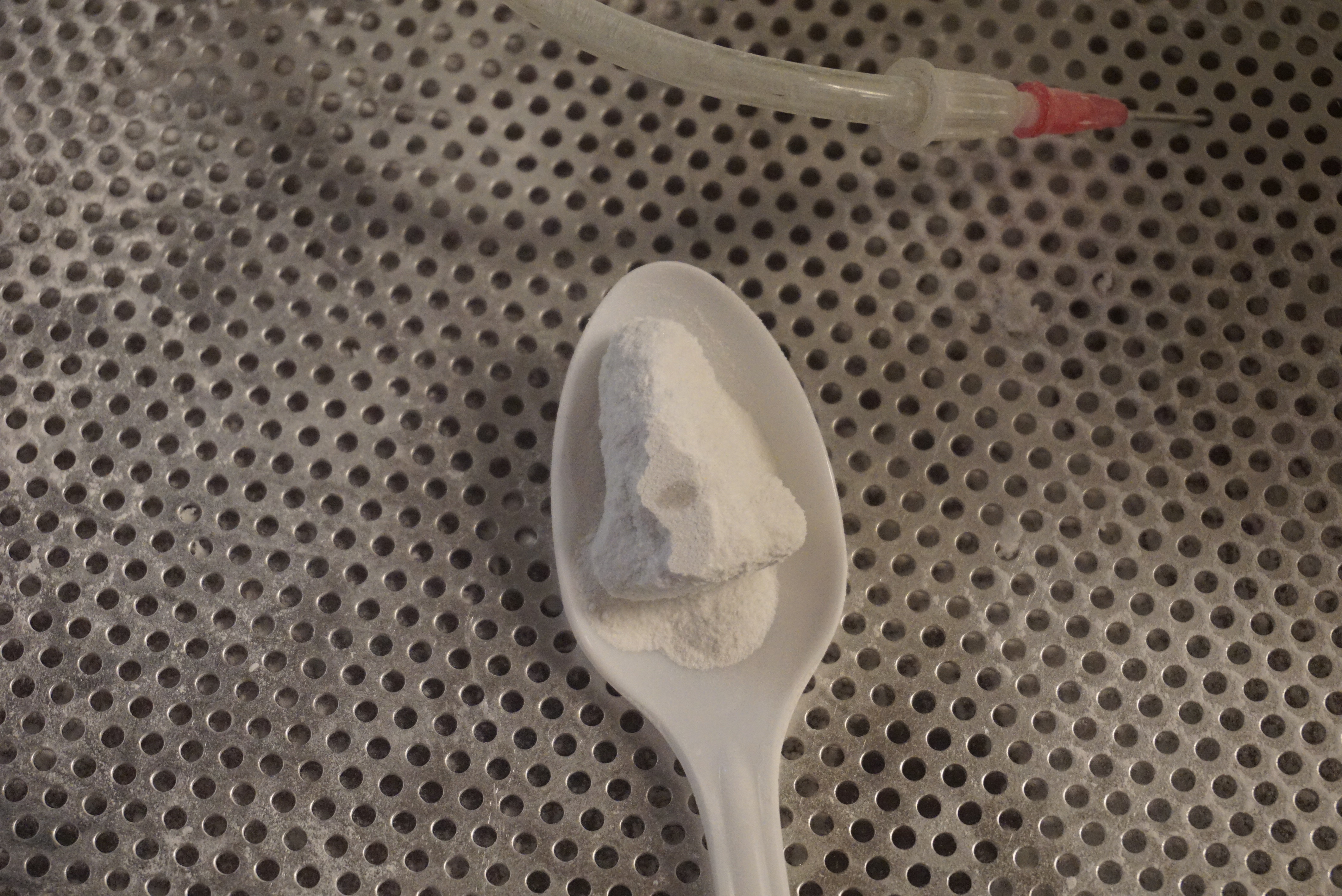

One problem. This machine needs absolutely enormous amounts of powder to print even the tiniest parts (compared to my own printers). Now all of this powder can be reused, but it still needs to be filled. Lets assume buying is no option and I need to make it myself. Obviously I am not going to test powders on a machine that needs 2kg of powder just to print a 2cm part, so I will need another way to test powder recipes. I do have some ideas, but with summer vacation coming up, I will not have that much time to work on it.

The bad news is that Z400 progress will be a bit slower from now on. I have worked hard to get the machine to work, but now I need powder recipes and binder recipes, and while I have some of them, I have yet to validate them, and I would prefer to do that in smaller amounts. HP45 related projects are expected from September onward.

So no worries, I will continue with the Z400, it will only take a few months to get everything ready.

Until next time.

Hello guys, I have Z core 510 for a long time. Now I’m looking for somebody to reproduce the same machine but with different look to be available to use for my artwork. I have the whole formulation for the powder and the binder. I am in United States Pennsylvania and if you’re interested we can get together and see whether we can do. My website is Deuxpan.com on the bottom of the website is my telephone and address. I don’t know where you’re from but I think if we get together it could be very interesting.

Nick

Nice write up.

What’s the expected resolution of the machine?

Powder resolution is usually more of a limiting factor, but I have 128 nozzles on a swatch size of around 10mm (I do not have detailed numbers). This should put the printhead in the 200-300DPI range.

Glad it’s still of some use!

I gave my Z310 to a local hacker space a few months ago, but still keep in touch with a few other Z310 users.

I did a lot of useful power material testing with just a spray bottle and a stencil, and a handheld microscope – you don’t need a full printer to get good info.

How the surface tension of the powder changes as grain size decreases is fascinating.

And I found that grain type, size and binder ‘wetness’ makes huge differences in how much capillary action occurs.

I had my best results when I had:

– About 1/2 layer (ie 0.05mm for a 0.1mm layer) of capillary extent from the binder droplet

– A combination of very fine rapidly absorbent ‘glue’ particles (ie sugar granules) and slightly larger slowly absorbent inert particles (cocoa powder in my setup)

– A small amount of oil (less than 0.1cc per 1kg) to allow the powder to maintain a water repellent surface on the powder rollers.

http://www.evillabs.net/index.php/ZCorp_Z310%2B#Materials

Lots of good information from my materials experiments on a Z310 (HP-10 heads like Japanese Sake!)

Good to see you again 🙂

Your site is high on my list of references. I do however still want to test smaller batches. Filling a Z400 (like your Z310) Takes an enormous amount of powder, and I would like to do more systematic testing. I want to make a tiny (think less than 20cm2) printer to test powders and binders on. I already know what I want, I only need to make it.