Home › Forums › 3DP printing › Step 2: conveying powder › Reply To: Step 2: conveying powder

I most definitely considered that, but hear me out.

For a next printer I am stuck with an idea, of making a printer that is as user friendly as possible. For this you need a hopper (like you suggest, or as I will show below), because preparing a powder bed takes skill. The problem with a top feeding hopper (and why I consider what I have for an idea) is that it takes a lot of vertical space. Combine it with pistons, and the printer needs to be massively tall.

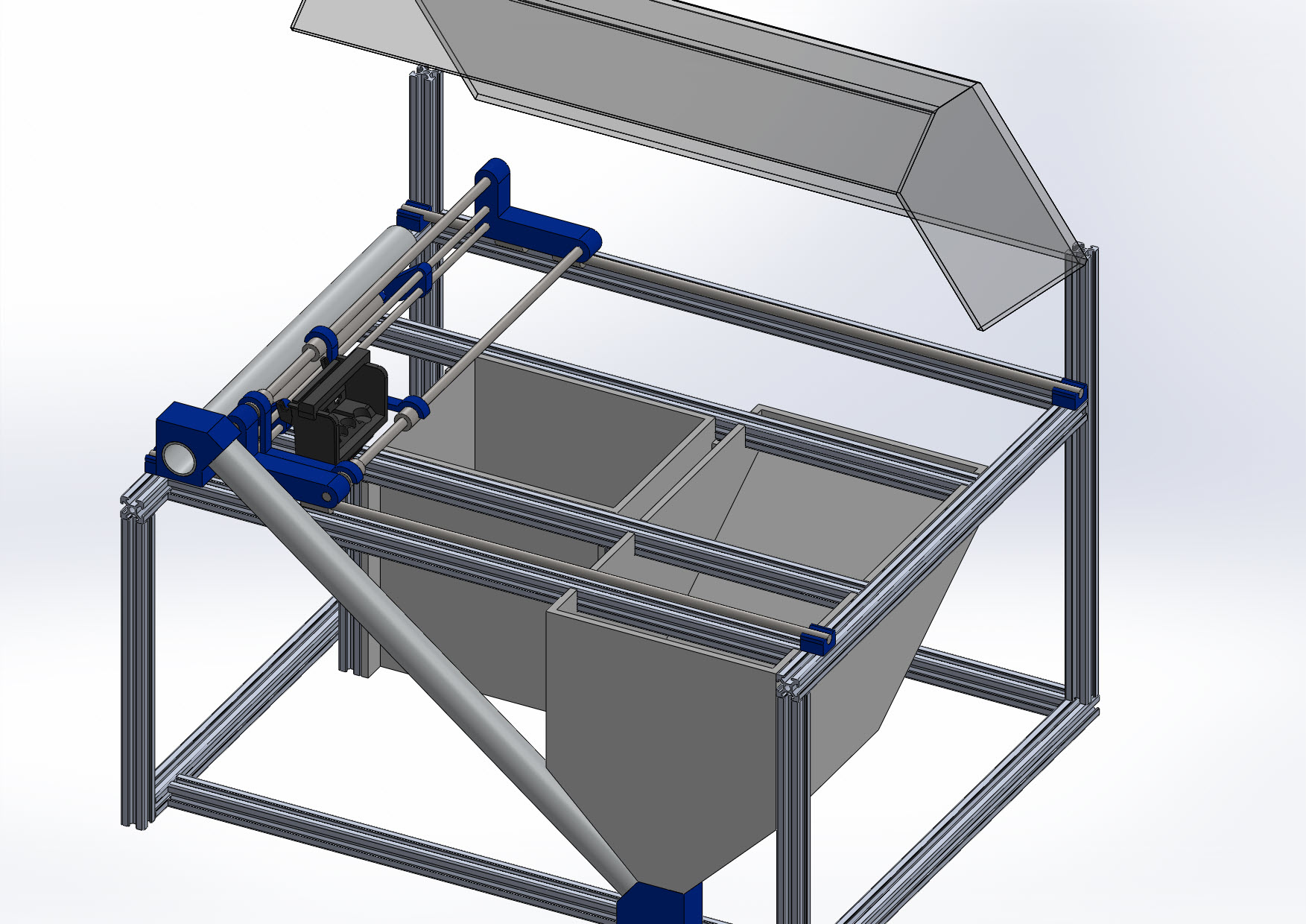

Here is my idea. A printer that has a hopper and piston design that requires no lead screws and guide shafts (based on cables and springs) and a side hopper next to the build platform. Screws convey the powder diagonally up and over the build area, where the spreader can pick it up (with a small opening mechanism). Any excess will fall back down, to the overflow, where a last screw will convey it back to the main hopper. The piston can also open up (like with Zcorps) and the powder will fall down to the overflow, where it too, gets pumped back to the hopper.

I admit this design does have flaws. For one it is more complex than other printers to make. Also, for people that want to experiment with powders, this printer takes forever to clean. To remedy this, I have an idea to make a small piston (with top feeder) that fits in the lowered build platform. This way, you can test small batches. I am still not sure if this is the right way to do it. It is complex and hard for open source to make, but it does offer ease of use like nothing out there.