Fallout 4 was anounced June 4th, and I was immediately hooked. I absolutely love Fallout and have been looking forward to Fallout 4 for years. One of the first things that was obvious is that the old pip-boy, the Pip-boy 3000, has been replaced with a different model, the Pip-Boy 3000 Mark IV. The new Pip-Boy has the buttons on the right instead of the left, and there are more buttons. It has a tape player on the top, and the opening mechanism is now defined. Now I rarely move aside running projects for something else, but Fallout is an exception. Time to make the Pip-Boy 3000 Mark IV 3D printable.

Now there is a difficulty with this project, there is only limited reference. The Pip-Boy is already extremely difficult to design with proper reference, but now there is only a teaser trailer and the E3 video. This does not give the kind of reference I usually have. Another challenge is the huge amount of features in the Pip-Boy 3000 Mark IV. I like to make as much features working as possible, and to get some of the features (most notably the tape player) working, was a real challenge. The people at Bethesda really tried their best to make the Pip-Boy as difficult as possible.

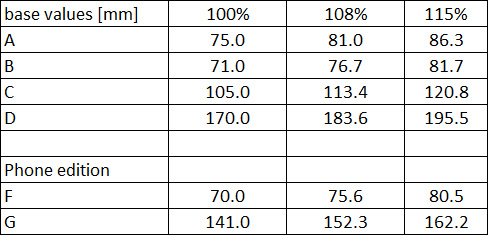

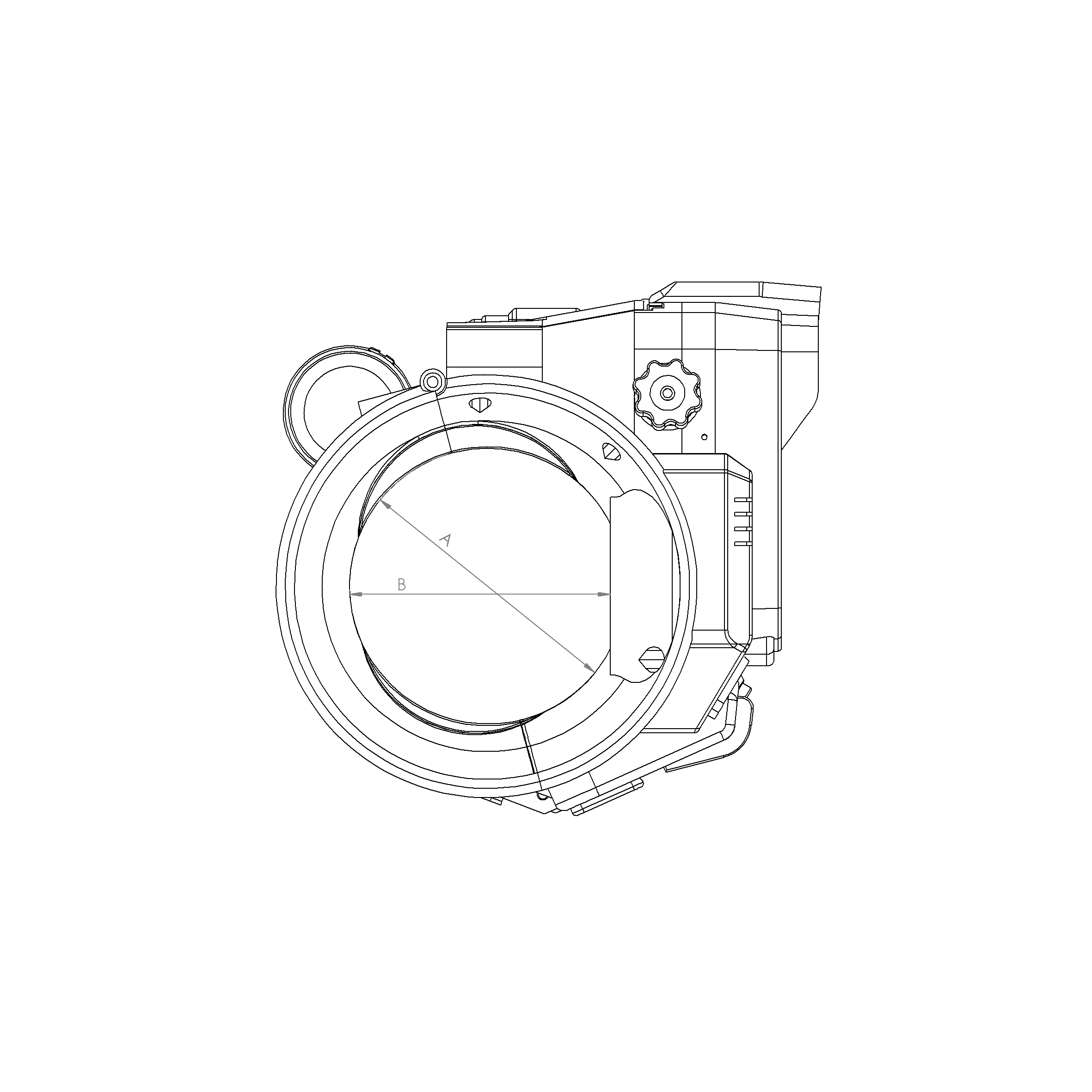

Another thing that was a real challenge was getting a phone to fit in this Pip-Boy. At the E3 it was announced that the collectors edition had a wearable Pip-Boy that could hold a phone, and so this 3D printed on also needed to be able to do that. There is only one problem. Smartphones have become bigger since fallout 3, and this Pip-Boy is smaller than the previous one. Bethesda has fixed this by breaking some of the proportions and dimensions to make a smartphone of decent size still fit. In some cases, dimensions are broken by around 1cm (which is way more than it sounds like). For the phone version of this 3D printed version, the proportions have also been broken to make the phone fit.

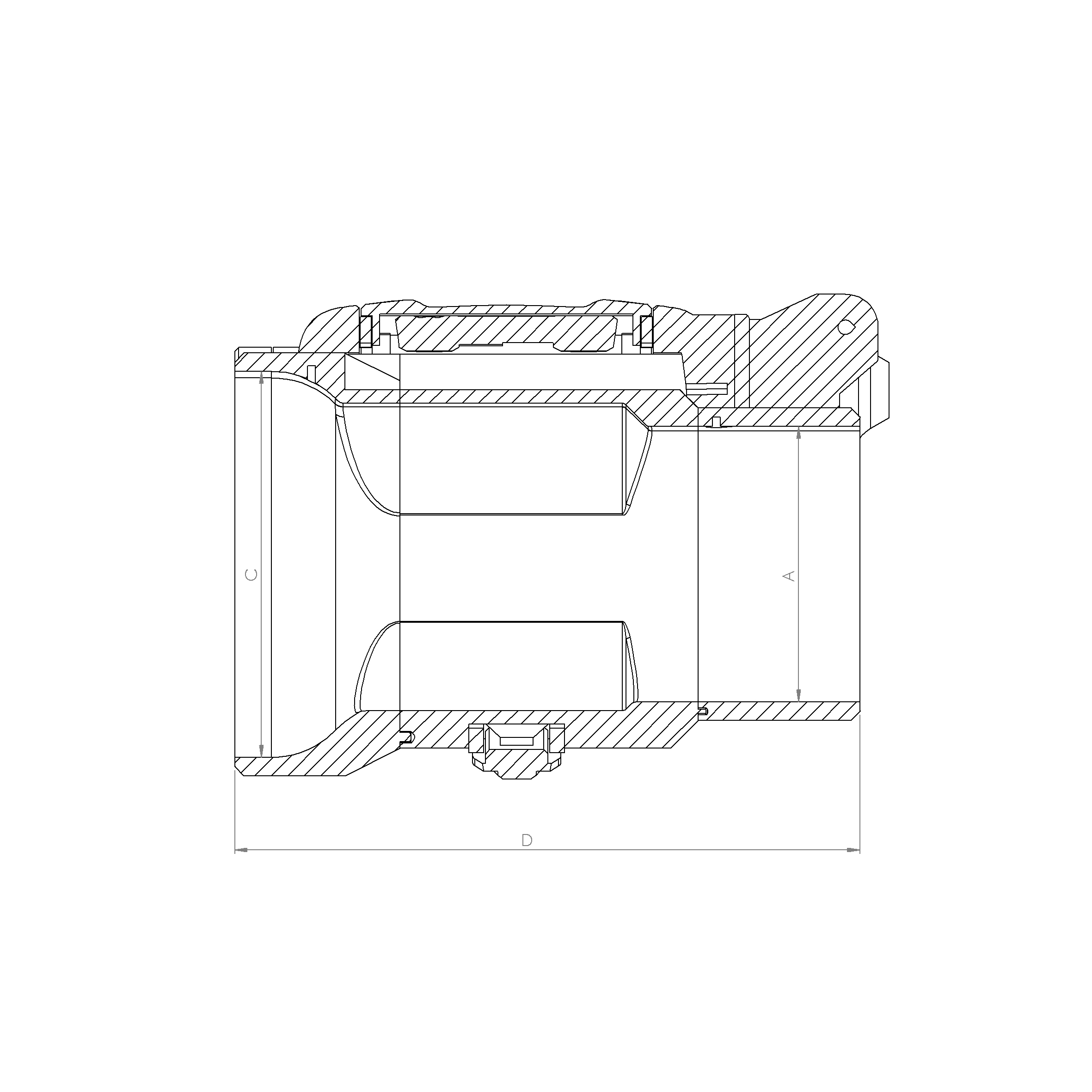

The 3D printed Pip-Boy 3000 Mark IV comes in 3 sizes. This is because the previous version, the Pip-Boy 3000, was already too small for some people, and the Mark IV is even smaller in some regions. Simply scaling the parts up is not only time consuming and prone to mistakes, it messes up the design. Some holes in the parts are designed for the screws to tap threads. If these holes become 10% larger, the screws will no longer fit. The standard sizes that the pip-boy comes in are: 100%, 108% and 115%.

The Pip-Boy 3000 Mark IV Phone edition is the version that will be most useful for most people. It can hold (as the name suggests) a phone that is within a certain size range. It is simply a case of printing it to have a usable Pip-Boy. To access the phone, 2 knobs near the tape player allow the front to come off. No tools are required to place and remove the phone (though it still take a half a minute or so). To make room for the phone, some of the buttons have been merged with the body of the Pip-Boy. It does have a latch mechanism and a tape player. The lights on the Pip-Boy can be 3D printed in clear plastic, and can be lit using colored LEDS. The gauges however cannot be lit, there simply isn’t enough room to fit lighting with the phone in the way.

(Edit 26-11-2015: The accurate version of the Pip-Boy 3000 Mk4 has been postponed until further notice. To design it I need to completely redo everything about the design (a 30 hour job) and I simply cannot find the motivation to do it with all other projects that I want to do. While I might do it at some point, don’t expect it to happen in the foreseeable future. My apologies to anyone who wanted the accurate version.)

The Pip-Boy 3000 Mark IV Accurate edition (not yet finished) is the version for the serious tinkerer. It is as accurate as I can make it, with no sacrifice to fit anything in. This version can be used to make a wearable Pip-Boy computer, but for instance using a Raspberry Pi. It has all the same tube dimensions as the phone version of the Pip-Boy, but the body may differ in locations. It is also advised to download the source files of the accurate version in stead of simply downloading the STL files and printing, to make the design and all the buttons for to the parts you have available. All mechanical features, the latch and tape player are the same as on the phone edition, but more buttons can be made moving and all of the gauges can be made to light up (or even better, made working).

Making it

Click on the button below to go to the making one page. Here you can find a comprehensive gallery of photo’s on how to make and assemble the phone version, plus all 3D printer files in .stl format of the released versions.

License

The project described on this page is licensed under the Creative commons – Attribution – ShareAlike license.

Thank you so much for this design. All the parts printed well. I’m currently assembling it.

Hi, I was wondering where to get these files? I’m probably stupid and overlooking it, but I don’t see any links to file sets

Did you ever figure it out?

Click on the image towards the bottom, above the CC license

Using this design, I’m going to modify it to fit a pi with 7 inch touchscreen.

Awesome idea!

What phones are people using? I printed the 115 phone version which came out great and my iphone 12S Max fits but the app is off center in the pip-boy. I guess because of the screen size, thinking i might get an old used phone thats smaller

I have a Samsung a12 what would be the best size for my phone? (Amazing work designing this by the way)

Okay so would it be a problem to sand or Dremel cut 1.3mm on the 115% Left and Right adding 2.6mm (Top and Bottom of Phone) If so, it will fit a Note 20 Ultra. I know it will fit the Note 9 as is which I have not sure if repair is cheaper then Cool otherwise may upgrade it and as you said rescaling could throw it off so figuring postproduction. Please advise.

where do it find the pi model

Its the best!!!

I have printed it and its the best pipboy ive ever seen!!!

Awesome work!!!!

The effort and amount of detail that went into designing and modeling this is just remarkable. For our version we were able to take apart a phone battery case, and hide the guts inside. This keeps the phone running longer without running down. We also did a slight mod to convert the hose into a USB cable, so we could connect the phone/charger to a power source without having to do a complete disassembly.

I ended up reworking one of the buttons to accommodate an on/off switch for the lights, and remixing the white spool thing on the back to allow the USB cable to pass through. I’ll put some of those reworked parts on thingiverse as a remix to contribute. USB Conversion is here: https://www.thingiverse.com/thing:4617803

Thank you for designing this is a way that allows for routing of wires and making adjustments (vs. all solid parts). And thank you for designing this to handle having nuts placed in the parts, so the plastic doesn’t get stripped out. And thank you for designing this with 3D printing in mind (tear drop shaped holes vs circles, peaks vs. flat interior surfaces so supports aren’t needed as much, etc.)

Just amazing thoughtfully designed work!

I have an iPhone 6+, what size should I use?

Best size for samsung s21 ultra? Id love to do this project

Awesome product man, but do you know if it would fit an IPhone 8, is in what percent should I dial the size up to?

Hey, will the accurate version be updated, or should I look elsewhere?

Hey there ehm should i use Supports for it (I have already used it for one but im now sure of i need to use it) please help me!

You should use supports for all the big stuff at the very least. It varies between printers, but it is a good idea none the less. I recommend getting some pliers or sand paper or even a dremmel if you have a steady hand for cleaning the pieces after printing. Sometimes the program fills screw holes and other bits with supports.

Really Your blog is very interesting, I also suggest to my friends to read your post. Thanks for sharing.

I hope my phone doesn’t fallout.

nice B)

Go stand in the corner

HI,you make so much interesting model ,but you don’t sale them,This makes me confused. so if you don’t mind i have two question want to ask you ,1 why don’t you sale them because it will be sale at a good price AND 2 ,what’s your job ,i ‘m a designer ,i have many interesting prototypes want to make ,but there is no time give me to do it ,all my time spend on my job .

Because of legalities. He doesn’t have the license to sell them, from Bethesda. Thus, he can’t introduce the product on the market for sale and distribution. He can give them away….and you buy him a six pack of beer. But there can’t be, legally, any exchange of capital for a product that is unlicensed by the proprietor of the Intellectual Property, that being Bethesda.

is it for sale im making a Fallout fan film and i dont have a 3d printer

I have seen them on etsy. I myself do not sell them.

I am a big guy, and I am more concerned about the Pip Boy fitting my arm. My wrist is 22 cm. around, and the largest part of my forearm is 34 cm. I think that means I need the 115% in order to fit, but I’m not printing it myself and want to be sure. I admire your effort and dedication. Thanks for the help.

It would be better is you did not measure circumference but width of the widest part of you wrist and arm. Arms usually are not perfectly round, and so will not give the right value. if you do use it, divide by 3.14 to get the diameter. This brings you somewhere between 100 and 108, but that is if your wrist is round.

https://learn.adafruit.com/raspberry-pi-pipboy-3000/overview will this Pi build fit into this chassis? Any sizing advise would be appreciated

I’m getting my parts in tomorrow, however whether it fits is purely dependent on how you mount the display. For mine (I’m using a poor quality 5 inch touch screen), I have to hack away at a part. However, with that part gone, it should fit nicely. I’ll inform you some more once I get this thing working.

Hi, so, did you managed to assemble it? I’m also plan to do Pi model with 5 inch screen, and interesting to find best size

Is this kit available on Amazon?

No, but I have seen kits on etsy

Im planning on making a pip-boy housing with the lattepanda, including a 7″ touch display, any tips or ideas on this would be helpful.

Only that you check the screen size. 7″ sounds awfully big to fit.

Does anyone know if you could make the holo tape have a storage device in it like an sdcard so you can use it to actually store data

I did it with a usb 3.0 right angle cable and a small USB drive

What size would fit a iPhone 7?

would any of these fit the S7? I do not have the S7 Edge.

I’m going to start printing mine soon! Im looking forward to it!

Really well done!

What size is for lg tribute 5

what size should i use for the galaxy J36 ?

Really love the Pipboy! (Almost done with one)

One thing I didn’t like is how you switched the LEDs on and off.

I used your “Right button 2” file and changed it so it holds a 8x8mm switch & wires.

This way you can use the top button to turn on the LEDs (or other functionality).

Here is the link to the redesign: http://www.thingiverse.com/thing:1736379

Hey, I wanted one of these for Halloween this year for a galaxy note 4… what size would be best, and can I get a link to the 3d printable model?

I’m sorry, I found the links, but still wondering about the size… thank you!

The Note 4 is a big phone, only the 115% will fit the phone.

i have galaxy s5 Its possible between 108% and 115%

What size should I use for a galaxy j7 v (pls don’t make fun of me) I think I should use 115% but not sure

what size would work best for iphone 6s

The 100% should already fit

Is that the 100% size fit to Asus Zenfone 6? My arm diameter was small (73 mm as I remember).

Hey can someone help me figure something out? Ive gottten a 3d print of this off of ebay, but he wouldnt trll me the size, according to the measurements ive taken, my pip boy is slightly smaller than the 100%! For instance the “c” dimension on mine is only 101 mm! Can anyone tell me if im missing something? Please reply I think he ripped me off!!!

With a C of 101, I doubt you have been ripped off. I admit it is somewhat small, but it is within a workable range. 3D printers are not perfect and so deviations can happen.

I live in a town where the ups store has a 3D printer but it looks like I have to have the CAD file in order to print. Any help on that and my only access to the Internet is a cruddy IPad so I’m not sure links would help much.

I know this is a stupid question but do the switches and dials work? It’s a bit of a deal breaker for me because I enjoy actually fiddling with them

Sadly, they do not. Including them would make it hard for people to replicate. I also enjoy working dials but I have to balance between ease of assembly and coolness.

dragonator, I was wondering, if I could sell 3d printed pipboys using your design. I am willing to pay you royalties for using your design. I am planing to sell them for $80 to $90 and will give you money for letting me sell them. I am an amateur prop builder. I have seen others on etsy (the site i plan on selling them on with your consent) selling your design and i wanted to do this the legal way. My father is a sabersmith by the name of Ing Chao and i want to make props as well. i was going to go to another designer by the name of Daniel Lilygreen of My mini factory but, I like your design better. please let me know how much you want per pipboy and if i can sell them. My email is jocobcox@aol.com

Would it fit a 5.5 inch Moto X Play?

What would be the size for a samsung galaxy s4

Does the LGG Pad F (8.0) fit

hey witch one of these would fit the galaxy s4 android phone?

does it fit a sony e3

What size will a samsung s5 neo fit? (142mm x 72mm)

hey so, I’m printing this out for my tech culminating project. my iPhone 6’s measurements prove that it should fit the 100%, but at the left side of the screen body piece the top part of my iPhone shows and it looks like it won’t fit. how do i cover up the top white part of my phone without wrecking it.

i really need help. if i don’t give an answer by tomorrow i might not be able to finish this project

So, if I have an iPhone 6, is the 108% size the correct fit?

100% should also fit the Iphone 6

Is the IPhone 6 ok with 108% or it requires 115%?

Hey, what size would fit a Samsung Core Prime?

will a galaxy s5 fitt

The 108% will

@dragonator What size will fit Samsung Core prime?

100% is fine

Would I have to use 100 for a galaxy S4 or would I have to use a bigger size?

100 is a tight fit, but it should be big enough

So i have a droid turbo (not the droid turbo 2) what size would fit it best, since it is a bit bigger than the iPhone6 and a bit thicker.

guys, I really want one, and I have a little trouble finding THIS one anywhere, can anyone send me links or someone who’s made one? I desperately need one

Check out 3Dhubs.com, you can upload the models and get them printed there. I have actually already printed 2 of these for customers (My hub is https://www.3dhubs.com/augusta/hubs/john). Looking forward to seeing their finished products!

On that note, does anyone know of a way to donate to the creator? Would be happy to give a donation for the orders I’ve gotten.

Nevermind, found donation page, lol.

you can contact grimlok2002@gmail.com,,i order 100% size lyesterday and i know he have 108% size complete painted in copper color ready for shipping,,

Hey ^^ I’m planning to print one of the phone variants on a CubeX Trio. Since I’ve got a Note 5 (153.2 x 76.1 mm) at the moment, would it be possible to use the 108% model and upscale it by 1% for an effective scale of 109.08% (153.823 x 76.356 mm) so it fits my phone? I would prefer not to print the 115% version, as I feel it’s unnecessary if the former is possible. Thanks in advance!

1% should not give any problems.

I’m sure it’s been said multiple times but what size would fit best for an iphone 6?

100%

how do know which size to pick, its so confusing

Anyone in the United States know where I can find these metric nuts/bolts/rods at?

Any hardware store. They have metric and US measurements listed on the bins.

My phone is Samsung Galaxy Grand Prime 144,80 x 72,10 x 8,60 mm

So as well as I understand, for me the best would be 108%?

I just wanted to ask if i should use the 100% or the 108% for my iphone 5c

100% should be plenty

Does anyone have dimensions on the holotapes that fit in the pipboy? I am experimenting with being able to insert an external battery with slight modifications on the pipboy.

i have a samsung s 3 mini what size would you recomend and if no presets were to work what should i use for the numbers

I have a Galaxy Note 4. Dimensions 153.5 x 78.6 x 8.5mm. Which size would you recommend me. Sorry i dont fully understand the chart. I dont want to order somwthing thats not gonna be useful. Thank you in advance

you would want the 115% size, if you go with the 108 your phone will not fit.

146,0mm -71,0mm

can my phone fit the 108% or should i better take the 115%?

108%

What size fit my 5′ – 5.3′ phone screen? 108% perfect or not? Pls help.. I cant afford to buy collector edition huhu

your phone would have to be practically square to have those dimensions, and if that is the case, none of these will fit

It’s a hyphen denoting range, not the width and height.

However the ambiguity is too great, just because you list the diagonal, it doesn’t say anything about the actual width/height of the phone itself.

Can it fit phone 4′-4.5′.. Like Alcatel One Touch Idol Mini? Which size is suitable? 100 or 108? Thanks!

Alcatel One Touch Idol 2 MINI will easily fit in the 100%

I was wondering to make it for my BF, he has the samsung galaxy s6 edge and it’s metrics are 70,1 mm in width and 142,1 mm in height. Should I go for the 100% or the 108%?

Thankfull for awnser 🙂

The fallout 4 pipboy edition Pipboy should work, it is a really tight fit, but it works.

The 100% will be extremely tight, I would go for the 108%

anyway i can just buy one already made? i really like this more than the others i have seen out there, hell it looks better than the actual prop that comes with the collectors editions and im not so good with this kind of build stuff

https://www.etsy.com/listing/253887409/fallout-4-pip-boy-3000-mark-iv-prop?ga_order=most_relevant&ga_search_type=all&ga_view_type=gallery&ga_search_query=pip%20boy%203000&ref=sr_gallery_9

I was curious about the dimensions of the actual portion that goes around the arm. Could you list the size of the cuff because I have a fairly large arm and have run into scaling issues when looking into other projects.

I have a xperia z3, 146 x 72 x 7.3 mm, would the 108% fit? I see it goes G 141 and then 152, should I do the 100% and sand it down to the 5mm difference, or will the with not fit?

I don’t think your phone likes being sanded 5mm, but you are not going to sand it from the Pip-Boy. Use the 108%.

Hi there, I noticed the minimum size was marked as 140mmx140mmx100mm, but I have access to a 2013 Cubify Cube that is 5.5in (139.7mm each way). Is that recommendation set in stone or able to change in small amounts?

It should be fine.

The phone size is 167.6 x 88 mm

Sadly, no. I have stretched and moved the design as much as I can. You’d need to scale up the whole design even more to make it fit, and that would make a Pip-Boy way too big. Your phone is simply too big for this design.

You could just sand down your phone…. XD

This made me laugh more than it should.

Quick question, I have the galaxy mega – (original) I just bought it and don’t want to down size for this, Could the phone port be stretched to fit?

We are offering seamlessly sanded MK IV’s with an option for a resin cast one in the 108% (Much more durable and lightweight).

https://www.etsy.com/listing/254927009/fallout-mk-4-pipboy?ref=shop_home_active_1

p

i have the facilities to cast aluminum, so i thought: would it be possible to print these parts and cast them in aluminum? is there any problems i should be aware of? also, what does the size mean (100%, 108% and 115%), is that the overall size of the pipboy or just the size of the screen/phoneholder, and what size do you reccomend?

There is a table with measurements that are related to the percentages. The size I recommend depends on the diameter of your wrist and the size of your phone.

As for casting in aluminium, you probably know more of that than me.

Does the 115% fit a Galaxy note 5 well?

If not which is best for a Galaxy 6S?

We can print it for you if you dont want the real thing from ebay.com

https://www.etsy.com/dk-en/listing/253367005/sale-fallout-4-pip-boy-mark-iv-pipboy-3d?ga_order=most_relevant&ga_search_type=all&ga_view_type=gallery&ga_search_query=fallout%204&ref=sr_gallery_3

https://www.etsy.com/your/shops/Grimlok2000/tools/listings/253887409

Does anyone know how much the pip boy would weigh when printed? (in grams)

He states that you will need a minimum of 500 grams to make this, so Im guessing that’s what the weight will be.

Solid work in Solidworks with this one!

Curious to see how long it will take me to make a remix of this replica. The prices mentioned to print something like this are outrageous to be honest. Will most likely go with injection molding since I have a bit of an OCD with reusing stuff. But in turn it should also cut the time form blueprint to prototype down to mere hours.

Once again, nice work with the design!

how do you get the schematics for it to be able to print. whem i downloaded the zip file it kept saying certificate trust list and wont let me veiw it.

stl is sometimes confused by pc’s to this file type. If you have software for your printer, you can open the files using that software and it will just open them. There is no default program to open .stl files.

I was wondering if there was an assembly file already built?

I so it would be extremely helpful if its also posted. Please and thank you.

Is there anyway you could email me the schematics for all the parts? Like the dimensions with all the angles and everything? I’m trying to make this on my own in my Cad class.

Short answer, no.

Long answer, no, it would take me an immense amount of time to draft those. There are also measurements that are almost impossible to put on paper, with complex curved faces. With the amount of spare time I have, it would take weeks.

Sorry, but I can not help with this one.

You didn’t create a project file or anything?

I do have source files and there are STEP files available for download, but there are no schematics. These projects go from 3D CAD, to printer to Internet without any schematics or drawings in between.

what program did you use to create the parts? Autodesk programs, etc?

Nice Job. But what size i Need for a Iphone 4 i got my 3D Printer and the pipboy ist my first Project now.

The rbeery Pi Version what a Display Hat can i Fit in the Pipboy (Zoll) ?

Great Job

Does this fit the iphone 4s if so what size to get??

The 100%. that will give you some spare room that you can fill in with some foam

Are these the actual schematics, as in all the dimensions for every part, or are they just the files to print. I want to make one as part as a project in a CAD class

They are just the STL files. If your CAD program can import STL’s you might be able to import it and get dimensions off it, but they are not schematics.

Thank you

Very cool. Currently about 40 hours into probably 60 hours of printing. I tend to print a little slower to make sure it sticks and to ensure a nice build. This first one I plan on painting. But also interested in printing out kits for those who might like to build their own. Still need to source out the misc parts to finish up the first build. So far, looking great!

Fully printed, did a dry assemble. Used ABS, due to shrinkage, assembly was tough when cutting threads. Regular screws were fine. This weekend I will be painting and final assembly. Will link some pictures once I finish final assembly.

Willing to sell printed kits (no hardware, no paint, no glue, etc) for $150. Your choice of ABS or PLA. Your choice of color. I will print on demand only, so lead time is about 5 days.

That is, assuming as Ytec3D is ok with me selling them.

I don’t know a thing about 3D printing, but would love to have one of these. What can you tell me?

This pip-boy, when printed, consists of 46 parts. Some are glued together, others use screws. Took me about 60 hours to print all the parts. Another couple hours to test assemble. This weekend I will be painting and reassembling. I will have pictures once I finish.

3D printers take a reel of plastic filament, melts it, and layers it till it builds up the shape you designed.

The two most common plastics used are PLA and ABS.

PLA has a lower melting point, so its usually easier to work with, and some details will come out better. It bonds with most plastic glues. Due to its lower melting point, it will soften at high temps (don’t leave it in your car during a super hot summer day).

ABS is a harder plastic. (legos are made of ABS) Some printers don’t like it because it is harder to print with. But the trade off is it stronger and sands a littler easier. Acetone will start to melt ABS, so one trick, instead of using glue, put a little acetone on the parts you want to join, and then push them together. When it dries, it will basically weld them together. Another down side to ABS is that is shrinks more when cooling than PLA. 2-3% So the final dimensions of your print could be smaller than the plans. This is evident when assembling my pipboy, as some of the screws can be a tight fit. I have a few minor gaps where some of the parts meet, which I might fill before painting.

I’d be willing to buy a pipboy from you, but it might take me a bit to get payment, is there any way i can get ahold of you to discuss payment details and shipping details?

Sorry for the reply delay. I can be reached via email at: michael@3dt2t.com

Hi guys, I am not too familiar with Fallout or what the Pip-Boy does lol but I run a commecial 3D printing website. I have actually gotten several inquiries for printing this unit so I am trying to put together a reasonable package for those that want one. What are you guys willing to pay for this if I can produce packages for you on a professional 3D printer? If there is enough demand I may be able to offer something at a somewhat decent price.

What would be the estimated cost of production with your equipment and materials?

Probably looking at around $300 for a complete set. I’m sure that is high but to be honest that is with very little markup on our end. Unless you have your own printer it just may not be feasible to have done. Let me know what you guys think.

By the way, the stl files I have been sent have a LOT of pieces. My recommendation was to combine some of these pieces (perhaps for parts that don’t move or have to be separated). That would allow me to lower costs.

Hi Yanus

Can you contact me rahelice@yahoo.com ,i will send you some photos and link ti completed Pipboy

Job completed and here is my video https://www.youtube.com/watch?v=SfpAcBVYMlU

I REALLY want to get one, and am willing to pay for it.

Anyone here will be selling completed version on etsy.com?

They currently only have outdated pipboys

And I am not sure about 3dhubs. They are not familiar with this project, and i’d rather buy it from someone who knows what they are doing, and not oblivious freelancer

When can I buy one

Here is a full-body view of the Pip-Boy 3000 Mark IV for you to reference for the accurate version. https://www.youtube.com/watch?v=YYA9mK6JSOo

Does anyone have a link with a person who is selling these?

Do you know what version I should get if I have a Samsung Galaxy S5 Active? Here is the information on the phone.

http://www.phonearena.com/phones/Samsung-Galaxy-S5-Active_id8665

Thanks in advance

If you look at the dimensions on your phone and compare them with the table above you should be able to find which one is the best for you. Make sure your phone is a little smaller than the dimensions given, as it won’t fit if it’s bigger.

I see this question a lot and for all the people that will still ask this, please use your brains and check it first. It’s not hard to find out, stop being lazy.

By the way, if you still are too lazy, you need the 108% version.

Is this Filament suitable for use in the creation of this Pip Boy?

http://store.3dprintingsystems.com/3D_Printer_Filament/Verbatim_PLA?product_id=247

All I can see is that it is PLA, so it should be suitable, but I have no first hand experience with that filament.

Just FYI. Somone has tacked the Rasberry Pi version and it looked pretty awesome. http://blog.ryangrieve.com/the-raspberry-pipboy/ if you’re interested.

https://bitbucket.org/selectnone/raspipboy/ <- A better attempt at RiPi program for the Pipboy.

I was wondering…will you make a stand for it? For display?

I have considered it, but thus far I am not planning on making one yet. Making a stand just like the collectors edition version would take a dozen hours to print. Too long for something that took 25 hours to print.

First at all,,,Thanks for beautiful design of Pip-Boy 3000 and new version Mark IV

I am printing new version divided in 4 print using Simplify3D software.Printing in high quality 108% model with 0,02 thickness and slow printing speed of layer will take more than 40 hours + assembly time .Print out give impressive WOW effect ,connection part perfectly matching ,,,My best ever prints coming out…Soon i release my second printer i will give effort to complete MarkIV soon as possible

Kind regards

Edard

Well, I thought this was amazing and could help me get a pipboy since bethesda failed to deliver :/.

But it seems that printing In the Netherlands is about €10 an hour. So if all parts take 25 hours to print well. do the math :'( if I would be ready to spent that kind of money I’d just buy a printer myself.

Am I calculating something wrong or is this seriously this expensive?

€10 is on the expensive side of reasonable. Some people ask that kind of money for it, and if you have a really good and/or really fast printer, you could. Normally, it should be something between €4 and €8, depending on the person, printer, material and print. 25 hours of printing actually is quite a bit of work.

I never claimed this model to be a cheaper alternative to the limited edition Pip-Boy, I made it for enthusiasts of Fallout and people with 3D printers (and most preferably, both).

Does anyone know if there is a design for larger (5.5 inch) phones?

yes the 115% is fora 6 inch phone

Any chance to ship it to Brazil? where can I look for? please send a link, thanks!

How much cost is printing that ? My friend told me that about 30€

There is about 15€-30€ worth of material in one (depending on the material quality), so if you already have the printer, it seems reasonable

Wow, thought thats cheaper. If i dont have it i have 3d printers in my city that can print it for me. Whats best material to print that beauty ? 😛

I am thinking to print one too, but I don’t have any printer and the local printer service charge too expensive for that. Anyone can find with a reasonable price for printing this Pipboy?

Is this possible to do with an Ekocycle Cube?

Should be. At the very least the 100% and the 108%.

I’m excited to try it, thanks for posting the specs!

no

Tom, our website provides a way of comparing prices of 3D printing services: http://compare-3d-printing-services.all3dp.com

Sadly you didn’t include 3dhubs.com also.

Hello! Please tell me: what% choose for my phone (Nexus 5). Thank you in advance for your reply.

Another question. Would you have an idea of how it would look if it was the pimp boy 3 billion mk 4?

Ugly, but my opinion about the pimp boy is not important here.

Painting it gold seems a good place to start, then paint all protruding edges and faces platinum or silver and add diamonds to some of the lower parts (such as in between the grille),

like this! (minus the diamonds)

Cool. But would you have an idea of where the diamonds would be?

PIP boy.. not PIMP boy…

Unless you’re being sarcastic.

Actually he means Pimp Boy, Pimp Boy was a custome gold colored pip-boy which you can only get in Fallout NV

I have an UP Plus in Australia, if any aussies want one printed, just let me know.

Whats the cost of getting it all printed?

You said you could print one can you give me a price and I’ll give it to you, contact me at alexnewyork505@gmail.com

Call me a noob but I am unsure how to tell which phones are compatable with which sizes (I have a galaxy s4). If you or anyone else could explain to me how it works it would be greatly appreciated.

On a second note, the accurate version says its coming soon(ish) however there are download files available. Have the accurate versions been completed, and are there any pictures or representations on what the finished product is supposed to look like? Thank you for all the work and I await your response. With regards Seth.

Also my phone size is:

136.6 by 70.6 by 8.6 (mm)

>Galaxy S3<

You could use the 100% with a bit work of a Dremel (the width is with 70.6 just a bit bigger) or the 108% with some filling material (like a shockabsorber for the Phone or some foam).

1. The 100% version should work for the S4. What you do to determine if it’ll fit is you look at the F(width of the pocket for your phone) and the G(length of the pocket for your phone)

2. Pictures are at the top of the post. The only thing that the current downloadable versions lack is the ability to turn the big knob on the right side of the pipboy because it is printed with the right side of the pipboy. I wore the pipboy at a local comic con yesterday and people wanted to know how I go one so soon.

How long did it take to print all the parts?

About 20-25 hours, depending on the printing quality

I’m printing at 100 micron, 3 outer walls, 40% infill, and just the Phone back 2 part took me 21 hours. The quality is amazing. Smooth and strong. Fantastic model!!!

would this fit the note 3 or would i have to adjust for the size of the phone

To figure things out for the phone, as best as I can tell you need to meet the parameters of the F and G dimensions. Please note, however, that these measurements are in millimeters, so you’ll need to convert your units of measurement to meet this standard. The smaller (F) dimension would be for the width while the larger (G) dimension would be for the length. While depth is not mentioned, as far as I can tell with a quick look, either foam spacers or a dremel could solve any problems with that I’d imagine, assuming youdon’t mind doing a bit of shaping and filling in the material afterwards.

when measuring the size of your phone to see if it will fit or not, do you measure the phone vertically or horizontally?

Which version can fit an iPhone 4s and/or iphone 5?

A quick Info for the ones of you without a 3d Printer. prab the files and go to 3dhubs.com there someone can print it for you.

Also I would mention that others on Thingyverse working on a Mark IV too. There are at least 3 WIPs I’m knowing of with these as the most complex one.

Please work together not only alone. I think together we would get THE Pipboy instead of several Versions

Just letting everyone know, one 3d printing site you can check to get this done with is http://www.3dhubs.com. They’ll connect you with local printers who could do the print. Was able to find one near me that will cost about $95 plus shipping for a medium-detail print in ABS. Probably going to be a mess to clean up since it’s only medium detail in this case, but I’m fine with putting in the extra effort.

Do not do this!!! This is incredibly expensive best price i saw was around £290. And that price you can make your own

So the price quotes im getting are 500-1000$ Canadian…. does that sound about right or am i doing somthing wrong?

Check the price of buying a 3d printer, I think your getting screwed by people who think their time is worth way more than it is.

Well it took me about 3 days to have everything printed properly. So I could imagine. (pro tip: the filament only cost me $14 ish and you gotta add paint and which takes another day or so.

Will the 100% version hold a galaxy s5?

Yes, because bethesda said theres could fit the galaxy s4 and s5 so if the 100% verzion is the same as bethesdas it will

Is there a place I could get the solids, I don’t have a 3D printer but I am a machinest so I could use them to make parts using a cad/came program.

Solids will be on the downloads page (under Support). They will be in Step format. By the end of this weekend I should have them there.

If you use raspberry pi can you make use of the dials and buttons?

Hey I have a question: I have a Wiko Highway and it’s 140x70x7,7mm. Will it fit in the Pipboy?

This is amazing! I was going to model this but you did a fantastic job!

When he says that it fits any standarized size phone he’s talking about an iPhone 5s up to a 6 Plus or something else?

Iphone 6+ is too big the iPhone 6 fits perfectly.

Will you create a version that can fit the iPhone 6+?

Get the phone 115% and it should fit an iPhone 6+

How to make a grub screw using a regular screw:

Materials: Screw

Tools: Dremel with metal cutting bit or hacksaw with metal cutting blade.

Pliers

Step 1: Secure screw with pliers

Step 2: Cut of the head of the screw with metal cutting tool (dremel/ hacksaw)

Step 3: Cut a ditch where the screw head used to be.

Done.

Thank you. That is actually the technique I also used before I got a stock of grub screws.

I’m having a really hard time with the latch do you have any more specific pictures of just the latch side but the exploded view?

(Edited comment)

The assembly guide is up. I can’t guarantee the text won’t change, but at least the pictures are there now. Hope it helps.

Ok thanks. Everything is done and painted I just need to finish the latch and screw the hinge together on the opposite side.

Pics: http://imgur.com/a/WCpzp

My god you work fast. You did in 3 days what took me over a week. Looking good though, so it doesn’t affect the quality.

I got at least 3 orders for people who want one. Going to comic con yesterday was a good thing. People were amazed by the pipboy. Do you mind if I sell them the printed parts? Also I was thinking about putting the parted parts up on my etsy page so it’ll be easier for people to get it.

Creative commons.

As long as you provide attribution, you can do whatever you want, so go ahead.

Way-to-go buddy! Fabulous job, looks great! Will be getting a 3D printer soon an this is on my list. Wonder if they’ll mind if I wear it to work?

can you make a left handed/right wrist variant pls?

You can mirror the parts before printing, that would basically do it.

can you make a left handed (right wrist) variant?

Great thing, but not anyone has a 3d printer to print this out… 🙁

Any chance of a file upload with less individual files? Maybe have pieces sprued together or some such?

I don’t own a 3D printer and looking around at various services they all seem to be limited to like 5 files a time with prices being pretty high all things considering.

Amazing work though.

It’s people like u bro! You’re the real heroes! Thank you! I don’t have a 3d printer, but I’m assuming there’s somewhere I can take this to, and they’ll do it for a fee. Anyone?

Wondering why for “PB3k Mk4 Phone body buttons 1” you didn’t make the knob a separate piece like the other knobs?

That is because the phone is partially in the knob. It needed to be this way to make a phone fit.

How long will it take to print this?

Around 25 hours on an UP! plus.

I will freaking pay you for this! No, seriously, I “need” a Pip Boy 3000 Mark IV. Name the price and I will save my money or bottlecaps for it.

This is an answer to everyone who is asking. I cannot sell any of these. I already have 10 hours too little in a day as it is, without selling Pip-Boys. 3DHubs can help you find a local 3D printer. Etsy has people who will sell completed versions (I already know one person who is working on it)

Please consider selling them! I am more than happy to pay for it!!

Can i buy one from you? instead of making it.

flodin

I don’t have a 3d printer. Is there a way to purchase a pip boy?? Id gladly pay for this it looks amazing. Or is there a place to go that has a 3d printer that’s available to the public?

Check out your local library, some of them have 3d Printers

thanks I will try that!!

New weekend project 🙂 thanks for this.

On “PB3K MK4 Phone front 2” some of the velcro holes are not extruded all the way through. I just used a hot knife to cut the holes out the rest of the way but for other people. I’m printing it all right now for a fallout 4 cosplay. You are amazing bro.

Noted, fixed and updated. A tiny feature mistake in Solidworks. Thanks for telling.

Thank you….THANK YOU!!!!!! They just announced that the collectors edition is officially done production and they will not be doing another run, unfortunately I did not manage to get one. I will be getting one of these at the earliest opportunity. The bonus with this one is that it has the opening tape deck and actual working lights!!! Though I suppose the Beth one could have those, but from everything I have seen it doesn’t. Going to get this, your Laser Pistol design, make up an armoured Vault jumpsuit and I have my Halloween costume for 2016!!!

You sir….ma’am? Not sure just found your site after hearing about the end of the collectors edition run. You are a God!

Is it possible for me to buy one of these as a kit?

Depends. The previous model had raw parts kits sell for around E60. They go on etsy, ebay and 3DHubs. They might come there in a few weeks/months. Else, 3D hubs also allows you to upload yourself.

Hi there,

This is incredible!!! How much would it cost to get one of these printed? Is printing these a service you could offer for those of us without 3d printers?

Keep up the amazing work – look forward to seeing your other fallout prop!