An orrery is a mechanical model of the solar system or parts of the solar system that can predict or illustrate the relative motions of the planets and moons. I have always found orreries fascinating, and when I found that there were no 3D printed versions of orreries yet, I was a bit shocked. I decided that I wanted to design my own version of the orrery, completely 3D printed. The orrery is within 0.1% accurate relative to the real solar system.

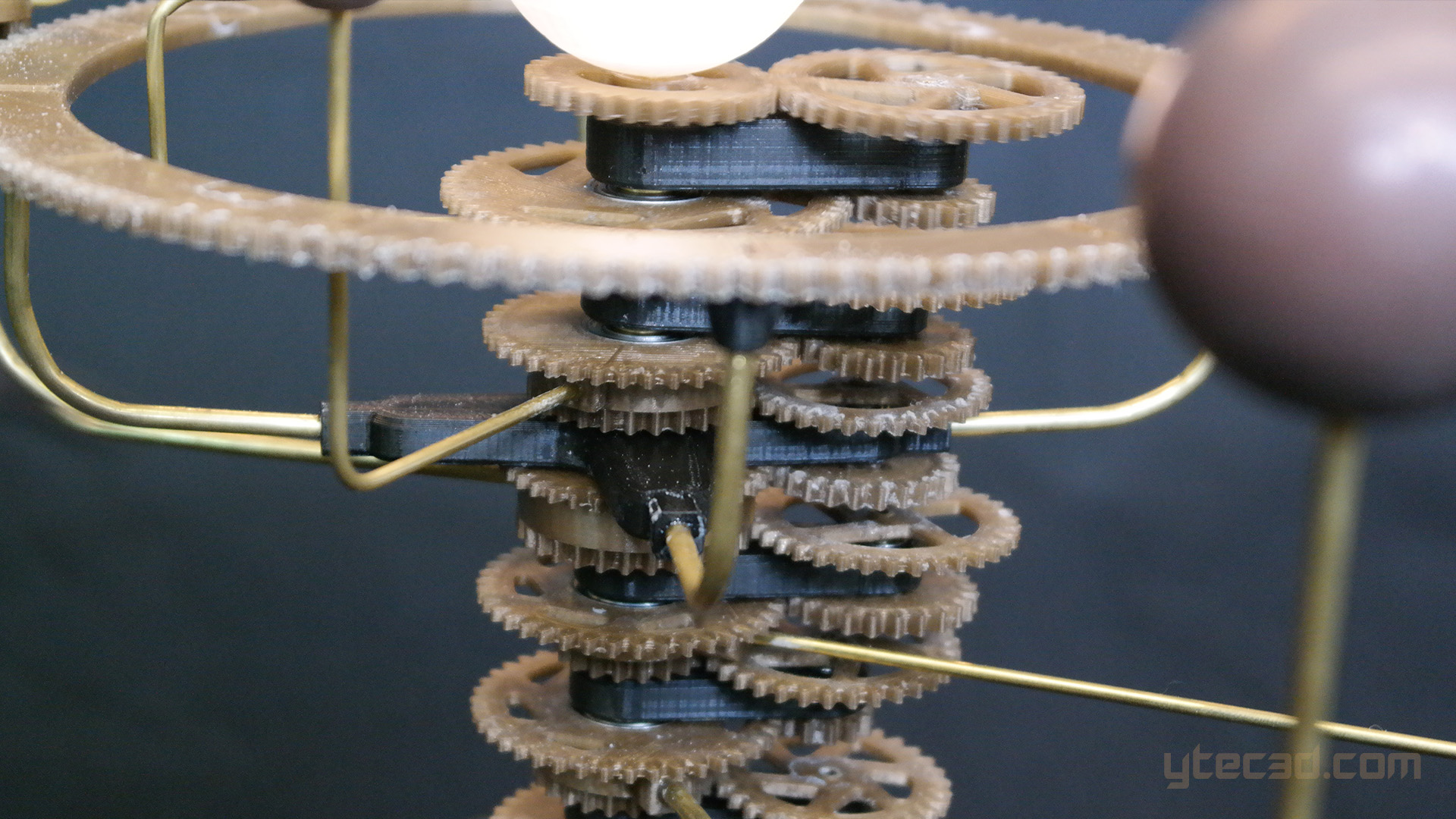

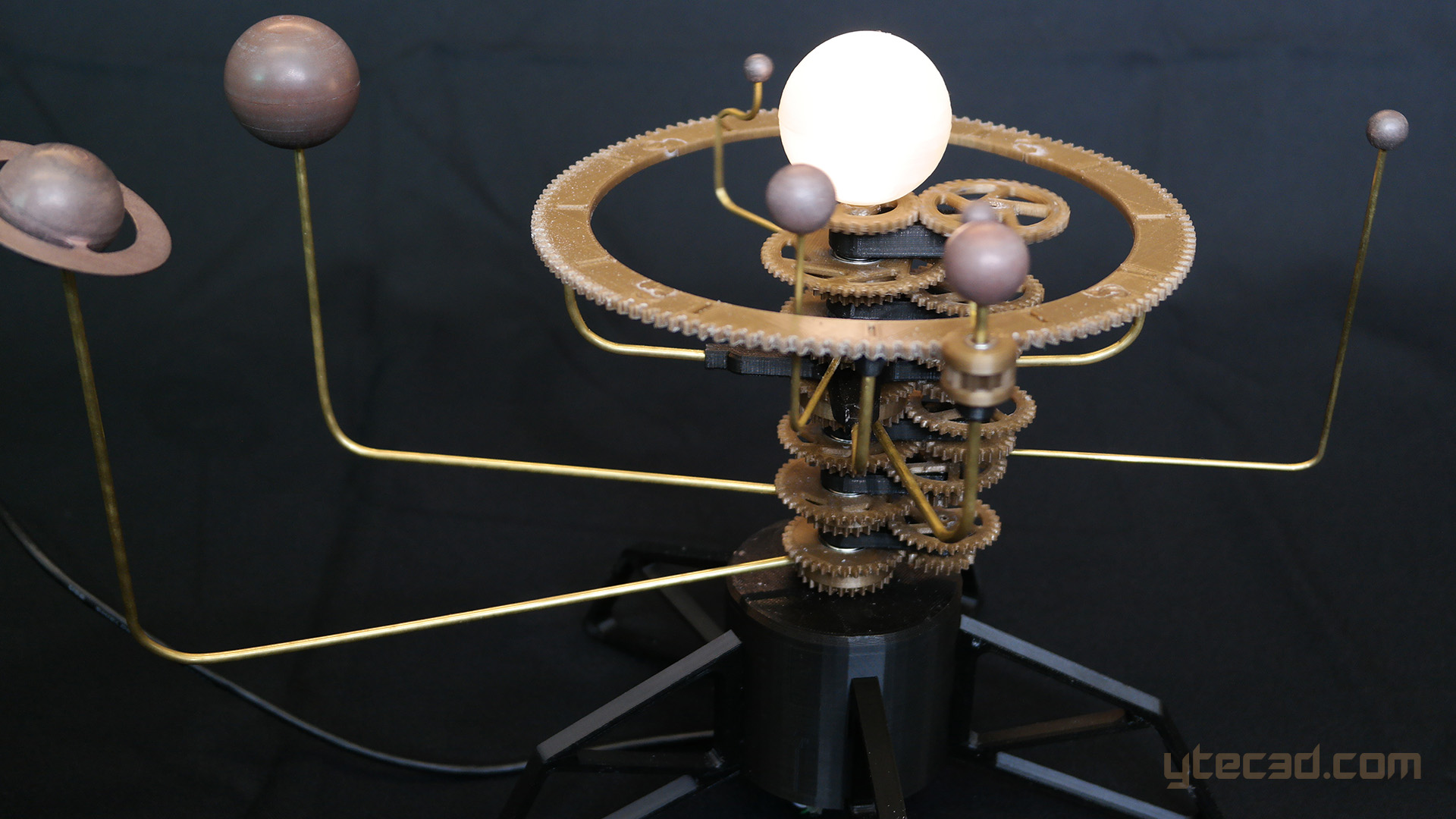

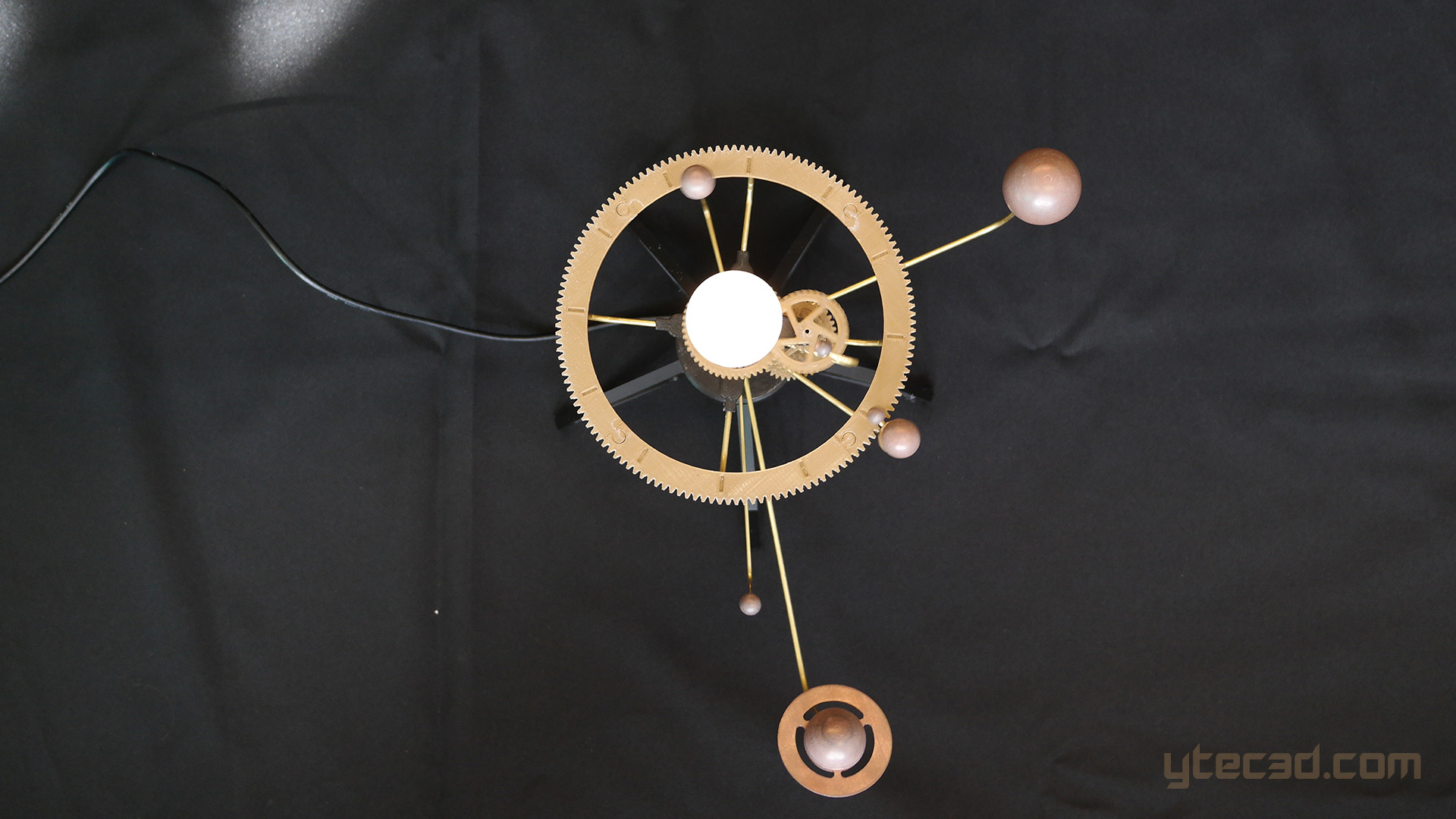

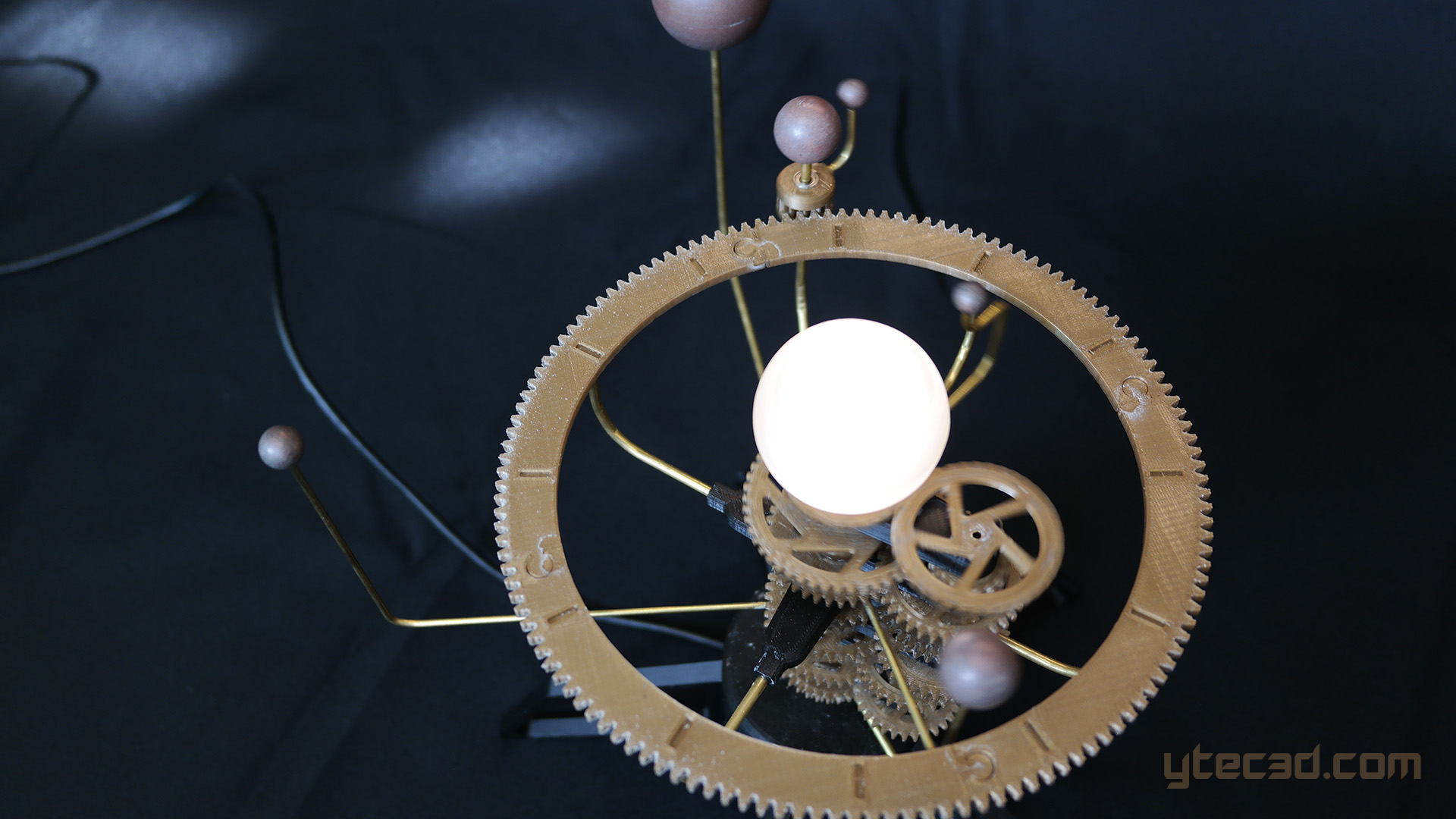

The orrery that is shared here is an orrery for the planets Mercury to Saturn. The sun spins and can be made to light up. The moon is also present, spinning around the earth. The whole orrery is made from 3D printed PLA. Gold for the gears, black for the frame, clear for the sun and Bronzefill for the planets and moon. All in all the orrery was printed in around 15 hours with a layer height of 0.2mm. To make the orrery run smoothly, all rotating parts use ball bearings. The base houses a small 5V motor that is powered by a USB cable. The sun is lit using Led’s and a slip ring is used to get the power to the spinning sun.

Uranus and Neptune have also been designed, but have not been incorporated in the main design. Both Uranus and Neptune spin really, really slowly around the sun and make the orrery incredibly large. On most old orreries they are also not included. For these reasons the 2 last planets were left out. They are still available in the downloads for anyone that does want these 2 planets.

To make your own you can download the files below and click this link to go to the assembly guide: https://www.instructables.com/id/Solar-System-Orrery-3D-Printed/

If you downloaded the files from this site and liked it, please consider going to the Donations page. This will help the development of more free designs and plans.

License

The project described on this page is licensed under the Creative commons – Attribution – ShareAlike license.

Thanks so much for creating this. I am currently printing out all the parts. However, I have a wrinkle – I really want to mount it from the ceiling, which means it would be hanging upside down. Is this likely to work, or will all the gears and parts fall off? I assume I will need to add in some clamps to keep it from sliding down the shafts, but is there any other reason it’s likely to fail?

Again, thanks! This is going to be awesome when I finish it.

The legs won’t work, but I do not see why the rest should fall apart, though I don’t know for sure. I think any issue you are likely to encounter can be fixed with glue.

Thank you so much – I am working on this now and will post about it if it works!

What 3D printer do you use?

Also, where can I get them? I checked the 3D printers tab and when i googled oasis 3dp, I couldn’t find anywhere to buy it from.

never mind, found the files

Would a filament 3D printer work for this project? Thinking of getting a 3D printer and have done some reading, powder 3DPs seem very expensive. Is it worth it?

Hello, Replying to all questions. Think this was printed on a weird self built Ultimaker, but any normal sized FDM 3D printer (around 200mm X and Y) should be fine. If I’d print it now I’d use a Prusa printer. Powder is only personal experiments, and not something used on any of my projects.

This project is awesome, however I am wondering if the planets’ size and distant are accurately scaled down, or if it’s just the orbital periods. Thank you!

If so, what is the scale?

Only orbital periods are accurate. Even the sun spinning is not completely accurate, because the sun is a fluid, and has no even spin.

Any orrery that is accurate in both planet scale and distance would be room sized, with gain of sand sized planets. Space is big, the gas giants are an order of magnitude bigger than the earth, and the sun is an order of magnitude bigger than Jupiter.

This is amazing! is there a file available where the large ring isn’t separated into 4 pieces?

Thank you!

There isn’t

I would love to own an orrery like this one. I have no way to build it though. Can you make one for me.. and how much would it cost? Thank you!

Sadly I do not. Maybe there is a Fablab or a Hackerspace close to you with the tools for you to make it yourself?

Marc Have you looked at any online printing options. they can print the parts and ship them to you for assembly. could even do metal parts

Hi! Currently assembling the orrery. I have one question about the gears that use the 688z bearings. Do I use two per gear, otherwise I seem to have 4 more than I need. Brilliant project. Thanks

The gears that use the 688z bearings do indeed need 2 bearings, one on each side of the gear.

Hi can you tell me how you got it to work? I am trying to make a similar design out of lego mindstorms for a school project but i have a problem. I can’t figure out how to get a layer fixed in place. It keeps on spining.

There needs to be a stationary central column. My orrery has all the big gears on the central shaft run on 8mm bearings. The only reasonable way I can think of is to use gears that do not spin on the central shaft, like the Lego differentials or the big hollow gears.

Hello!

Amazing work btw. Im designing an orrery of my own, but would love to use your excel file for finding your gear ratios. Would you mind explaining how it works? I cant tell which numbers are supposed to be what in your second sheet. Thanks in advance!

Hi there,

I purchased all the materials as per the instructions, however, I’m having a hard time fitting the 688Z bearings on the 8mm central shaft. I double checked the bearing and it appears to be the right size because I can see 688Z written on the it, and the inside diameter is ~8mm. Considering the bearings and the shaft are the same size, it makes sense that it would be a tight fit, but I feel that it shouldn’t be this difficult to slide them onto the shaft. Does this sound right to you, or should the bearings slide right on?

In my case the bearings slid right on, maybe check the outside diameter of the rods?

hello congratz for the project its amazing. im trying to bring this project at my final exmas at school, but im gonna ask you, if possible, all solidworks files in order to modify a bit it, and put my sign just in some parts. it will be appreciated to have as much files as possible too.

thanks again