Home › Forums › 3DP printing › Possible ABS Printing Recipe?

Tagged: acetone ink cartridge

- This topic has 22 replies, 4 voices, and was last updated 9 years, 10 months ago by

wonko.

-

AuthorPosts

-

October 9, 2014 at 8:22 am #1672

SliceOfBrad

ParticipantHey guys,

I am a big 3D printing fan, but ever since I got into it I wished that there was such thing as a full colour DIY 3D printer. Thanks for making my dreams come true! I was thinking about a possible recipe for the powder and bonding agent. I haven’t done any further research on the matter, but I know that acetone dissolves ABS plastic. Would it be possible then to use fine ABS powder and use acetone mixed with the ink? The problem then would be if the ink cartridge or print-head is also dissolvable by acetone, but I don’t know what plastic they are made of. Like I said, I don’t know much about the topic and can’t do any testing myself unfortunately, but would any of you know if this is possible?Thanks, Brad

October 9, 2014 at 9:37 am #1673dragonator

KeymasterHello Brad, welcome,

I don’t think your dream has completely come true yet, but work is being done to make it happen.

The idea itself is intriguing and worth investigating, but I myself am also not sure of the effect acetone would have on printheads. The good news, the C6602A is made of fiber reinforced nylon (for some dark and mysterious reason) so it should be resistant to acetone. The nozzles themselves are a bigger mystery, since there is a lot of very fine technology in that area.

It should also be possible to 3D print in ABS powder with a less agressive binder, and then use the acetone vapor technique to cure the part. This way acetone does not have to go through the printhead and you will still have a ABS printer with no support (and shrink). The part will be a bit weaker though.

October 9, 2014 at 1:53 pm #1676ezrec

ParticipantThe HP print head chip itself is all silicon, and should survive acetone.

The surrounding plastic and flex cable – I wouldn’t bet on it.

However!

As acetone is my favorite solvent, and as I have a spare dead cartridge, I’ll stick one in a jar of acetone and see what happens.

Best case scenario: full survivalist.

Good case: flex cable and print head survive, and that will allow us to bond the print head to a milled metal cartridge to hold the acetone.

Worst case: a single bare silicon chip floating in goo.

And speaking of goo – instead of printing with pure acetone, how about printing with an acetone/plastic mix?

That, combined with incrental baking, should cause less wicking of the acetone through the powder bed, and a stronger part.

October 10, 2014 at 3:55 am #1678ezrec

Participant

So, looks like no appreciable change in the exterior of the cartridge after immersion in 100% acetone for 2 hours.

I’ll let it sit for another 24, then inspect by disassembly.

(No, I won’t put an acetone filled inkjet cartridge in an enclosed space with DC motor spark generators around it to test if it still prints!)

October 10, 2014 at 3:56 am #1679ezrec

ParticipantAside: GAH! This lack of post preview is KILLING me…

October 10, 2014 at 4:40 am #1680ezrec

ParticipantDid some research. ABS is easily dissolved in acetone, polystyrene a little bit, but the PTFE of most ‘cheap’ cartridges should hold up to the acetone.

Unfortunately, from your pictures, it seems that the HP CN642A has ABS components.

So, maybe if we can reverse engineer some of the cheaper HP cartridges, we may be able to print ABS powder with ABS+Acetone as a binder.

All depends on if acetone + ABS turns into a fluid, goop, or slurry.

October 10, 2014 at 8:44 am #1682dragonator

KeymasterI have placed a post in the site and shop thingy about the preview problem, I have had it myself as well and it would probably be better to fix it while this forum only has 20 posts and 4 people.

About the acetone. I could have sworn the cartridges were made of PA, but now that I think of it, it could also be the carrier. I will see this afternoon what material it is made from and follow-up. ABS becomes a thick fluid when subjected to acetone. Use too much acetone on a part and it will melt. When the acetone vaporizes, the ABS will resolidify. It should ‘sinter’ the grains of ABS powder together if all goes well. Now lets hope that acetone and C6602A cartridges like eachother, because the idea is interesting.

October 10, 2014 at 6:46 pm #1703SliceOfBrad

Participant<p>Thats what i was thinking when i came up with the idea dragonator. Instead of weakly bonding together the powder and strengthening it after the print is finished, it would solidify each layer together as it goes hopefully getting rid of the post processing. plus vapor smoothing could be done afterwards to further finalize the part. Thanks for sacrificing a cartridge ezrec! Excited to see the final results!</p>

October 10, 2014 at 7:40 pm #1705dragonator

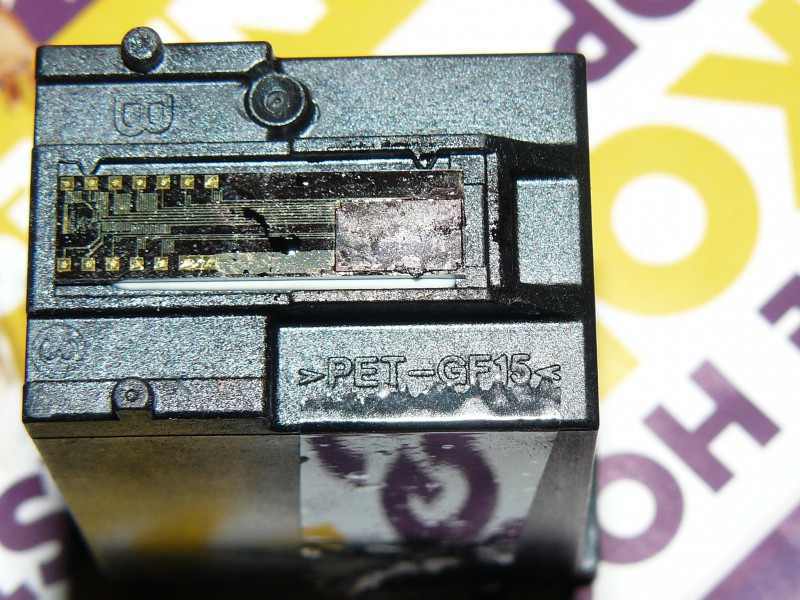

KeymasterGood news and bad news. The good news is that I start to like the idea more and more. The bad news is that the tests will probably not be preformed with a C6602A cartridge.

It is not fibre reinforced PA, but it is 15% glassfiber reinforced PET. This gave me hope, but when I looked up the datasheet for PET, it showed poor resistance to Acetone. PET datasheet

The CN642 has no material identifier, so I do not know what that one is made of. I will see what else I can find, perhaps I will try and see what acetone does to a C6602A for real in stead of just reading the theory.

October 10, 2014 at 7:58 pm #1706

October 10, 2014 at 7:58 pm #1706ezrec

Participant<p>Drill out small dust samples and test those, no need to ruin the whole printhead</p>

October 10, 2014 at 11:42 pm #1707ezrec

Participant<p>Dell series 1 cartridge test result after 24 hours in acetone:</p>

- No external mechanical changes to the casing (ie softness or stickyness)

- Flex cable fully intact

- No apparent mechanical changes to the print head

<p>Now to pry it open without getting ink everywhere…</p>

October 11, 2014 at 1:55 am #1708ezrec

Participant<p>No damage to the ink foam…</p>

<p>

</p>

<p>No damage to the interior…</p>

<p>

</p>

<p>Ok, looks like this cartridge type (Dell Series 1) could be used for acetone/ABS prototyping!</p>

October 11, 2014 at 10:13 am #1709wonko

Participant<p>Oh, very nice! Thanks for trying this out. Do you have electronics to control the jets?</p>

October 11, 2014 at 1:57 pm #1710ezrec

Participant<p>My Dell printer guts are in a pile right now, non operational, and I have no ink to run through the cart anyway.</p>

<p>That, and hacksawing it open has ruined it for printing – the cartridge needs a partial vaccuum to keep the ink from dripping out.</p>

October 11, 2014 at 8:17 pm #1711wonko

Participant<p>Hmm, well, it would be great to know the connections on the cartridge. This looks like a matrix one. If we can control it, we can mount it on a Plan B machine and print with Acetone on ABSS powder… .</p>

-

AuthorPosts

- You must be logged in to reply to this topic.