Table of content:

- Part 1: The beginning

- Part 2: Electric overhaul

- Part 3: PC power

- Part 4: Trying to print

- Part 5: (you are already here)

- Part 6: Leaky pistons

- Part 7: Making printheads

- Part 8: Printing in powder

Really, Ink

A shorter blog today, but quite a milestone. The Z400 ejected its first ink. In the previous post I was stuck with a few options as to why the printhead was not printing. I have spent a few hours testing, and ultimately found the issue.

The first suspect was that BX-20 != BC-20. Simply slapping in a BC-20 (an original one too) resulted in the exact same result, nothing. A few attempts were made to print with the old, converted printhead, but the ink connection is not functional anymore. I did not figure out if it is to do with the CISS system. The ribbon cable was measured to check for breaks, but all signals seem to be working. I was running into dead ends.

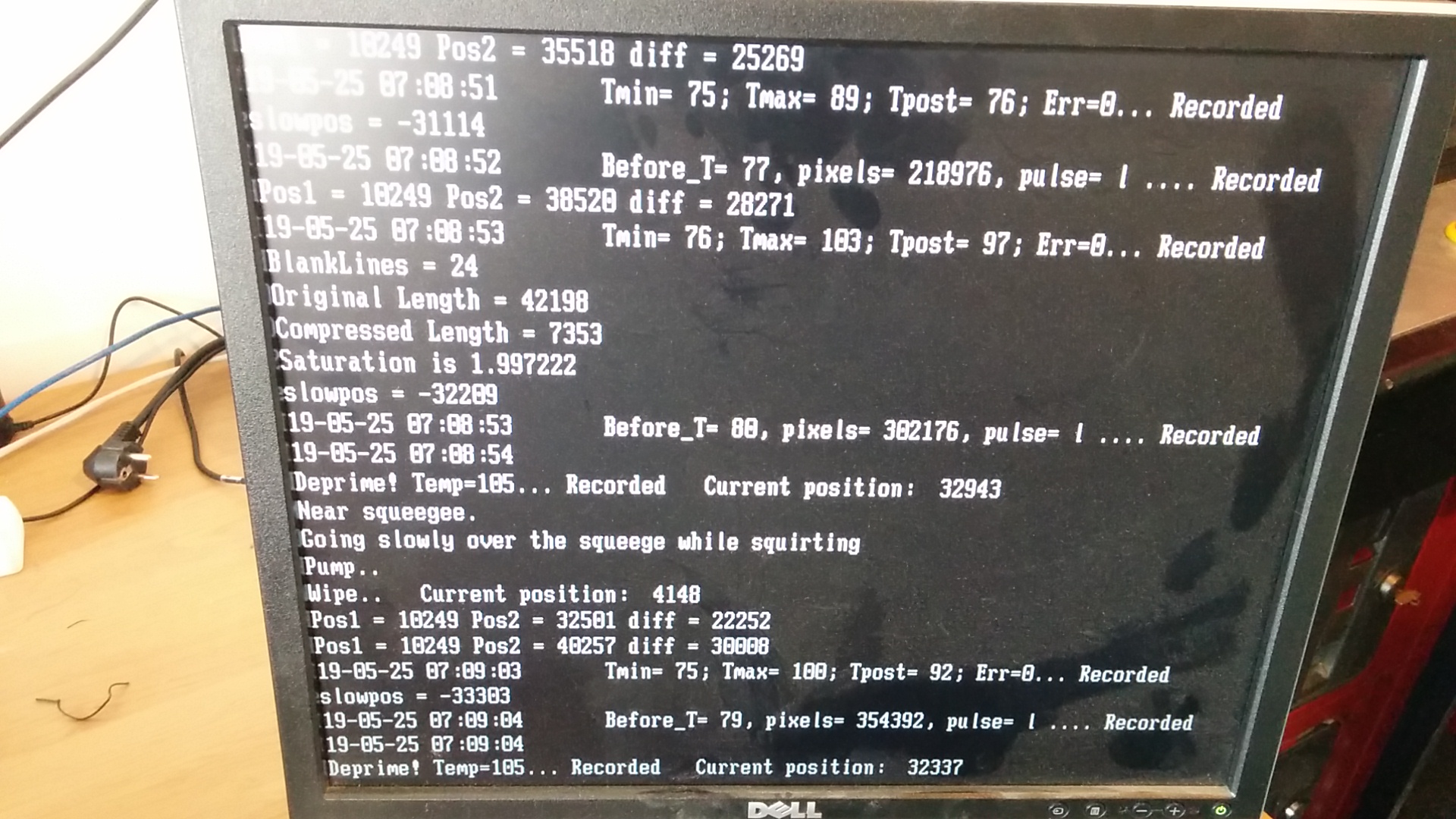

One attempt gave a critical clue. During a print, the printhead would print one sweep, then stop to flush the head with new binder (which did nothing, since we were printing with normal printheads). This would repeat every other sweep. A quick glance at the screen told us what was wrong, the head overheated, which triggered the printer to try and flush the printhead.

The Z400 was printing, but ink was not getting out of the nozzles, keeping all the heat in the head. This was also confirmed by the fact that wiping the head with a paper towel showed no ink.

Armed with this knowledge, I tried applying a vacuum to the nozzles to draw ink through. We lacked the tools I needed, so I almost got a mouth full of ink, but there was now ink in the nozzles.

I loaded the started printhead in the printer, and pressed print again. Almost instantly, the printer printed a perfect image. An observation I made is that the printhead deposits an unholy amount of binder on the surface. I knew it required more than an ordinary inkjet printer, but 5 layers of ink on cardboard warped the paper. The software suggests this took over 1ml of ink (the head only holds 44ml). I now understand why CISS heads are used.

Below the obligatory video of us printing (the Tkkrlab logo seemed appropriate).

Now that I am actually capable of printing, the last big hurdle seems to be cleared. The printer is now capable of printing. There are still plenty of things left to do. The thing that usually starts the printhead is the dock. It has a vacuum cup to start the head. This is obviously not working, requiring me to do it myself. The pistons seem to leak, requiring me to make a new seal. I also still need CISS printheads. All things for the future.