Hello and welcome to a blog that is a bit different than what I usually do. A repair blog of how I attempt to revive a Zcorp Z400.

Table of content:

- Part 1: (you are already here)

- Part 2: Electric overhaul

- Part 3: PC power

- Part 4: Trying to print

- Part 5: INK!

- Part 6: Leaky pistons

- Part 7: Making printheads

- Part 8: Printing in powder

The Zcorp Z400, what is it

With no wikipedia article available, there is not a nifty list of features and when it was released, but here goes:

The Zcorp Z400 is a relatively ancient 3DP (powder and inkjet) printer. The manual is copyrighted 1997-2004, so that puts the Z400 at least at 1997. Hilariously enough the user manual completely fails to mention how big the Z400 can print, but it’s probably around the size of an A4 (200x300mm) by 200ish vertical. Once I know, I will say.

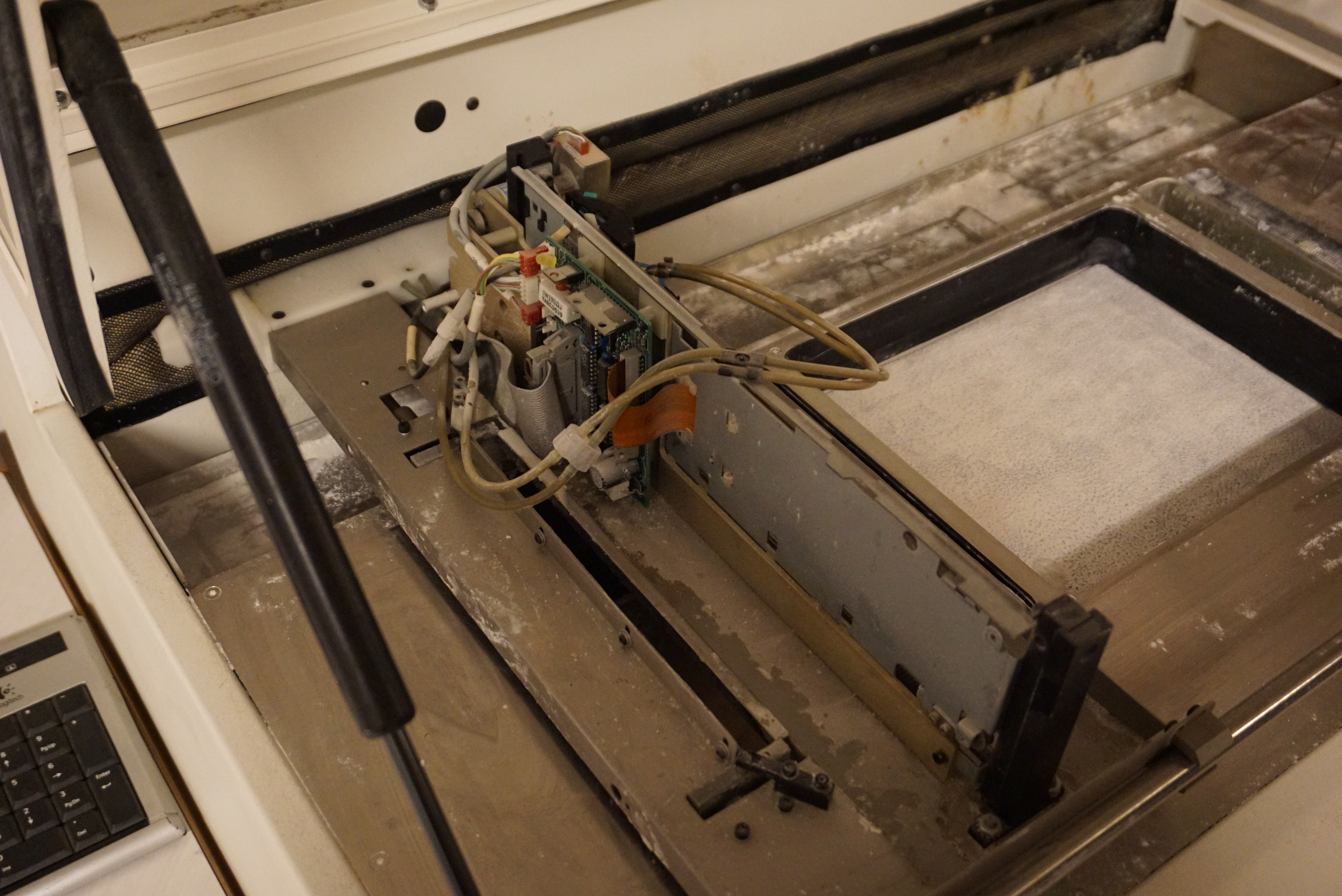

Also quite interesting is that the whole mechanism of the Z400 says ‘robust’ and ‘industrial’ until you reach the printhead gantry. The whole gantry is sheetmetal from an ordinary old inkjet printer that uses Canon BC-20 printheads. The Z400 uses modified versions of this BC-20 that are no longer available, but there are alternatives to make yourself: http://blog.freesideatlanta.org/2011/07/making-print-cartridges-for-z400z402-3d.html

The BC-20 heads have no DPI known, but should be 128 nozzles since the manual speaks of 128 jets of binder. Again, will say when I know.

A summary of the Zcorp Z400 is that it is a big standing 3DP printer from the time when 3D printing was unheard of, running an old PC (more on that later) controlled through serial, controlling a hacked Canon inkjet printer to print in powder. There are plenty of motors and pumps and pistons to make it all work, but that is the summary.

Why and how I got it

“But Yvo”, I hear you say, “how did you get this Z400?”.

Good question, here is how: https://ytec3d.com/forum/viewtopic.php?f=8&t=5627

Wonko donated it to me. It has not been running for half a decade and he wanted it somewhere where it might be used. Getting it to my house was quite an adventure, revolving around a too light car, a too big trailer and a town celebrating carnival.

It currently sits at the Tkkrlab in Enschede while I repair it.

What I want with it

Obviously I want an working 3DP printer from a real original 3DP printer builder. And since there are boatloads of patents involved, there are only 2. Zcorp, and the company that bought Zcorp, 3DSystems.

I got into 3DP because I love the concept of 3DP, and my goal is to print ceramics with this. I will investigate other materials, and will continue work on my own 3DP and inkjet adventures, but I also cannot pass the opportunity to get experience with an original printer.

What needs to be done with it

The machine has been sitting still for the past few years and is already old by itself. There is no guarantee that this blog will end at page 2 proclaiming the PC as dead and irreparable. But I will try my best to make the original work, and else replace all that is printer with my own electronics.

This is the short list of what needs to happen before I can even start to print:

- HDD needs to be tested. If these fail, the printer is dead. (Spoiler alert, I did already make an image of my drive, this still works);

- Power supplies need to be tested outside the printer (it is a 110V machine);

- Computer and boards need to be tested. The computer needs to start and run, and the printer needs to want to move at least;

- Binder lines and printhead ribbon cables need to be tested and or replaced;

- All movement needs to be checked and lubricated. The build piston probably needs a new seal;

- Printheads need to be made;

If I did not forget anything, that is what I will need to do before I can start to print. Here is hoping that the machine is still in working order.